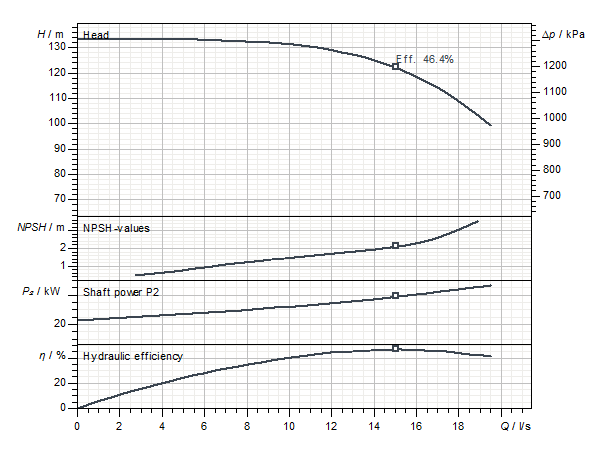

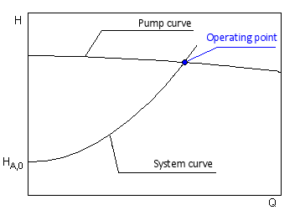

The required shaft power of the pump is given as a performance curve depending on the flow rate. The performance curve changes when the speed of the pump changes in accordance with the affinity laws.

The shaft power of the pump is directly proportional to the density of the pumped medium. In the case of highly viscous media, the shaft power also depends on the viscosity.

Depending on the application and size of the pump, the drive is designed so that the motor power is either greater than or equal to the viscosity of the pumped medium.

- the shaft power at the operating point or

- the maximum power of the characteristic curve,

in each case plus a security surcharge of at least 5%.

The required safety margin depends on the required engine power. While the safety margin is reduced to up to 5% for larger motors, surcharges of over 20% are applied for smaller power values. In addition, the nominal motor power for standard motors must be converted to the ambient conditions.

P

2 is used as the symbol for the shaft power.

In addition to the Q-H performance curve, the following performance curves are often found for centrifugal pumps:

In addition to the Q-H performance curve, the following performance curves are often found for centrifugal pumps: