Month: February 2021

Jacobs Engineering Group Inc.

Density

The mechanical power requirement of a centrifugal pump (shaft power) is directly proportional to the density of the pumped medium.

P 2 ~ ρP 2 = shaft power

ρ = density of the pumped mediumIn contrast, the throttle curve of the pump H (Q) and the efficiency η (Q) are independent of the density.These relationships are automatically taken into account by the pump selection software.

Pumped medium

In particular, the following criteria must be taken into account:(1) General suitability of the pump type

In principle, centrifugal pumps are only suitable up to a certain viscosity, which depends on the size. A positive displacement pump should be selected for very high viscosities.(2) Pump characteristics

The pump characteristics are usually measured with water under standard conditions. If the density and viscosity are different, the characteristics must be converted accordingly. This is usually done automatically by the pump selection software if it is a Newtonian fluid.(3) Material selection

The selection of suitable materials is extremely important, especially if the pumped medium contains abrasive or aggressive components. Many manufacturers offer media resistance information for this. For such use, however, direct contact with the manufacturer is definitely recommended.(4) Seal selection

In addition to the media-material resistance, the characteristics of the pumped medium must be taken into account when selecting a suitable seal. In the case of dangerous substances (e.g. toxic or explosive media) or particularly valuable fluids, it is usually necessary to use a leak-free solution. Pumps without a shaft seal with a canned motor or magnetic coupling are ideal here.(5) Solid or gas fractions

If the pumped medium contains solid and / or gas components, special pump designs that are intended for this must be selected. For example, suitable impellers prevent the pump from blocking when there are solid or fibrous components. Gas proportions affect the suction behavior of centrifugal pumps. A higher gas content leads to an increase in the required NPSH value and thus to the earlier occurrence of cavitation.

Mains frequency

Due to historical developments, a mains frequency of 50 Hz is used in Europe, Asia, Australia, most of Africa and parts of South America, while a mains frequency of 60 Hz has become established for the public power grids in North America.The specification of the mains frequency is necessary for the selection of the electric drive. For pumps that are operated with single-phase or three-phase motors without a frequency converter, the synchronous motor speed changes in the same ratio as the frequencies, i.e. from 50 to 60 Hz by a factor of 1.2. In accordance with the affinity laws, this also changes the pump’s performance data.A frequency converter is often used to adapt the performance data to the operating point. The electrical energy drawn at the mains frequency is converted into a voltage with a different frequency in order to change the motor speed.

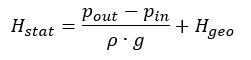

Total static head

It consists basically of two parts:

- The pressure difference between discharge side and suction side tank. It is zero for open tanks and closed circulation systems.

- The height difference between the liquid levels of discharge side and suction side tanks respective the system inlet and outlet. It is zero for closed circulation systems.

Pump comparison with known operating data

- Select your country in the PumpSelector.

- Select the category (for the example “water supply”).

- Enter part of the search term in the Tags field and select “Borehole pumps” from the autocomplete list.

- Filter the series list by the desired manufacturers, if necessary.

- Enter the duty point (in the example flow rate 10 l/s, delivery head 50 m, total static head 35 m and click on Search.

- The list of results is sorted by efficiency; click on the compare symbol in the row of the desired models.

- Open the pump comparison via the menu.

- Add the desired pump to the shopping cart.

ComAp a.s.

Selection of a known pump

- Select your country in the PumpSelector.

- Select the category (for the example “Heating, air-conditioning, cooling”).

- Enter part of the series name in the Tags field and select the desired series from the autocomplete list.

- Click on the magnifying glass icon behind the series to display all models.

- Click on the model name to see the technical details of the pump.

- Click on the shopping cart symbol in the result list and switch to the shopping cart.

- Compare the shop offers and go directly to the desired shop.