That means that the local atmospheric pressure p

b is higher than the sum of net positive suction head H

H and vapour pressure p

v; the inlet pressure is thus no longer required. This interrelation is based on the drastic reduction of the vapour pressure of cold water. In practice, that means:

Pumps operating at a negative minimum inlet pressure H

req are capable of creating a suction lift (not self-priming).

The suction capacity is approximately equal to the level of the negative minimum inlet pressure minus 1m safety factor.

As pumps normally used in conjunction with building services are generally not of selfpriming characteristics, the following conditions for suction lift operation must be met:

- Filling and venting of the suction-side pipework including the pump before commissioning.

- Avoiding air entrainment during pump operation (aeration will result in break-down of suction capability).

- Avoiding drainage of suction-side piping on standdown of pump by providing and installing a footvalve (danger of leakage due to dirt particles).

Reliance on non-return valves in the discharge pipe is not sufficient, as air can be entrained by way of the shaft seal (mechanical or packed gland seals) on pump standdown.

The suction capability of non-selfpriming pumps is, on account of their construction features, generally limited to the range of max. 2 to 4 m. Higher suction lifts (max. 8 to 9 m) and selfpriming operation require the use of Special Pumps.

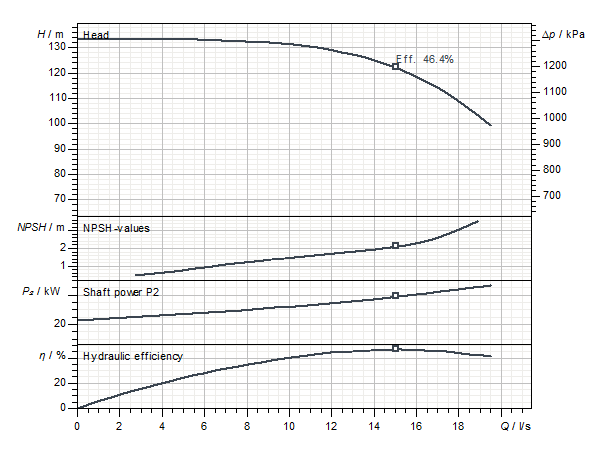

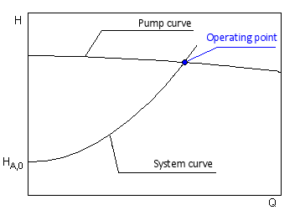

In addition to the Q-H performance curve, the following performance curves are often found for centrifugal pumps:

In addition to the Q-H performance curve, the following performance curves are often found for centrifugal pumps: