- Filling and venting of the suction-side pipeline including the pump before commissioning.

- Prevention of air intake during pump operation (in case of air pockets, collapse of the suction function).

- Prevention of the suction line running empty when the pump is at a standstill by using a foot valve (danger of leakage in case of contamination).

Suction operation with normal priming centrifugal pumps

This means that the local air pressure p<sub>b</sub> is higher than the product of the holding pressure head HH and the vapour pressure and makes a supply pressure at these temperatures unnecessary. This correlation is causally related to the drastic decrease in vapour pressure at cold water. In practice this means:

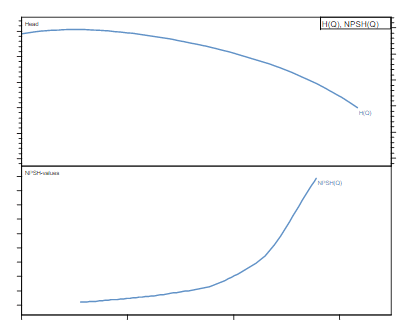

Pumps with negative minimum head H<sub>req</sub> are able to operate in suction mode (not self-priming).

The size of the suction capacity corresponds approximately to the value of the negative minimum suction head minus 1m safety range.

Since the pumps normally used in building services engineering do not normally self-priming, the following conditions must be met to ensure suction operation: