Reich Presents Torsionally Stiff Flange Couplings for Pump Drives

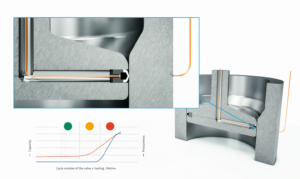

RCT Kupplungen - powerful and reliable drives. (Image source: Dipl.-Ing. Herwarth Reich GmbH)

RCT (Rubber Coated Tooth) couplings allow for both sub- critical operation and damping and thus offer the optimal drive solution for the connection of diesel engines to hydraulic pumps. They are particularly appropriate for all hydrostatic drives which are used for example, in construction machinery. These long-lasting, maintenance-free RCT couplings also find their use in ship and harbour engineering and in railway applications – at ambient temperatures from -25°C to +100°C.

The high torsional stiffness of the RCT couplings ensures that critical resonances typically occur in the range above the operating speeds, enabling the sub-critical operation of the drive without passing through the detrimental torsional vibration amplitudes. Minor axial, radial and angular offsets which are common to flanged hydraulic drives are compensated for at the same time. 'Our RCT couplings convince through the use of elastomers in lieu of plastic material. In addition, we offer these as a backlash-free and maintenance-free shaft- hub connection. Because we develop effective and efficient coupling solutions in line with our guiding principle 'Designed to Customer' for our customers who request tailored and special designs to meet their individual industrial requirements', says Johannes Hock, the technical manager at REICH.

Versatile and fail-safe

RCT couplings are designed as axially pluggable flange couplings. Numerous standardized tooth profiles are available to ensure a backlash-free clamping connection between the RCT coupling and the pump shaft. In addition, we offer all standard SAE connections for the engines. The RCT couplings can be additionally equipped with appropriate bellhousing flanges for almost any mounting situation, which carry the weight of the attachment pump(s) via the engine housing. Each RCT coupling furthermore offers an inherent fail-safe function by design – also known as 'get-home device' in marine language – which enables power transmission even in the case of failure of the elastomer. One of the essential quality factors of our couplings is our in-house development and advancement of the elastomers for use as a damping element.