AFRISO Introduces New Heating Pump Assembly

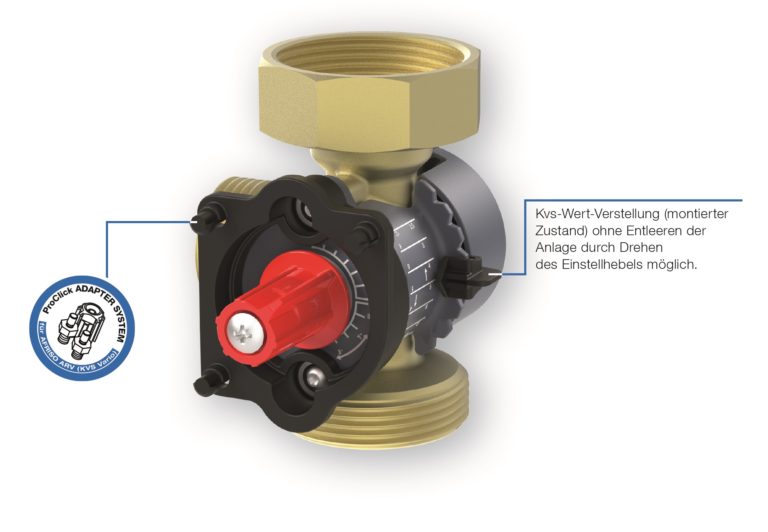

The AFRISO heating pump assembly PrimoTherm® 180-2 DN 25 KVS Vario offers not only an actuator that can be mounted without tools, but also a further sophistication: a 3-way mixing valve with an adjustable flow coefficient Kvs. (Image source: AFRISO-EURO-INDEX GmbH)

It covers a wide variety of requirements with maximum efficiency and reliability. Three versions are available with nominal size DN 25 – all of them pre-assembled, tightness-tested and heat-insulated. They are available with optional high energy efficiency pumps. Now, the range is getting even more powerful: The new 3-way mixing valve ARV 325 for the heating pump assembly PrimoTherm 180-2 DN 25 KVS Vario offers maximum flexibility right down to the construction site and facilitates hydraulic balancing.

The flow coefficient is an important parameter in hot water heating installations and plays a key role in optimum heat supply to the heating surfaces. So far, mixing valves in installations had to be correctly rated before they were mounted and adjusted to the required flow coefficient Kvs of the system. In the case of planning errors or design changes, the valve is usually not properly designed. A mere estimation of the flow coefficient Kvs often leads to malfunctions during operation.

A mixing valve that is not correctly rated or not rated at all usually leads to frequent on and off cycles of the heat generator which becomes inefficient, and by undesirable noise in the hot water supply piping.

Adjusting the flow coefficient Kvs without draining the system

With the new 3-way mixing valve ARV 325 as the core component of the pump assembly, such challenges are now a matter of the past. The clear, easy-to-read scale lets you set the flow coefficient Kvs to a value between 2.5 und 12 m3/h at any time – even without draining the system. For initial mounting, the flow coefficient Kvs can also be set with a standard slotted screwdriver at the rear of the mixer. Tanks to the easy adjustment of the flow coefficient Kvs, incorrect rating is therefore a thing of the past. Handling is just as easy, down to the last detail: an adapter on the mixing valve is used to attach the AFRISO ARM ProClick actuator at the correct position without tools.

More efficiency – from warehousing to installation

Optimum adaptation to the respective control requirements of the system entails lasting benefits: Smaller volume jump/smaller, minimum controllable power, larger valve authority, and full use of the entire mixer control range (0 to 100 %). Hydraulic balancing is also significantly simplified because the power required to heat the heating surfaces is available and can be used. The flexibility of the 3-way mixing valve also has practical advantages for both wholesalers and heating system professionals: The variety of pump assemblies is reduced which simplifies storage logistics.

Powerful system assemblies in three versions

The new 3-way mixing valve thus successfully rounds off the functionality and variety of the PrimoTherm system assemblies. The versions of the PrimoTherm DN 25 are tailored to a wide range of requirements: The version 180-1 is used in non-mixed heating circuits, especially for storage tank charging. Version 180-2 was specially designed for mixed heating circuits. With the 3-way mixer and the actuator, the flow temperature can be adjusted to the desired temperature by adding water from the return. Good to know: PrimoTherm 180-2 can also be used with solid fuel boilers to raise the return temperature*. Version 180-3 automatically controls the return temperature of the system water to the heat generator to the value adjusted in the valve. All versions feature a deactivatable gravity brake integrated in the ball valve.

Installation individually or side by side on AFRISO boiler manifolds

The system is modular so that the flow line can be mounted at the left or the right side. Each pump assembly is shipped with a high-grade mounting kit for wall mounting. Due to the slim design, it is also possible to mount several pump assemblies next to each other on AFRISO boiler manifolds.

All circulation pumps offered by AFRISO meet the requirements of the European Ecodesign Directive (stage 2 as of 2015). The universal insulation allows for the installation of virtually any standard pump without reworking of the insulation. AFRISO pump assemblies are also BAfA-listed* – a key benefit for unbureaucratic subsidies. For example, private persons, companies or municipalities get back 30 % of the net investment costs through the "Federal funding for efficient buildings - heating optimization". With the PrimoTherm assemblies and the new mixing valve, heating system professionals are in a perfect position to meet a great wide variety of installation challenges.

* Control required

Source: AFRISO-EURO-INDEX GmbH