New Pump Control Panels Ensure a Great New Year for Caribbean Fuel Terminal

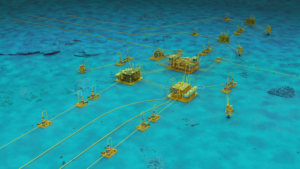

Sulzer has extensive experience in designing and manufacturing drives and control panels for pumping systems (Image source: Sulzer Ltd.)

Thankfully, Sulzer was able to design, procure all the necessary components and produce two panels ahead of schedule.

Located in St Croix in the U.S. Virgin Islands, Ocean Point Terminals is the largest marine storage facility in the Caribbean. Recently, it needed to expand its operations and plans were going well until they started looking for a supplier to design and build two new pump control panels. Several potential suppliers were contacted, but none of them could meet the delivery deadline of mid-January.

The call to Sulzer in mid-November was almost their last hope. Fortunately, the leading independent service provider (ISP) has extensive experience in designing and manufacturing drives and control panels for pumping systems and was able to support the customer. In fact, the project was fast-tracked and a delivery date before the end of the year was confirmed.

The first step was a phone call between Sulzer and Ocean Point Terminals to discuss the technical specifications of the new drives and the details of the application, which may affect the way in which the pumps operate. The pumps were 125 HP (93 kW) and the plan was to install them for oil transfer operations.

From this, a complete list of components was created and priced. The quote from Sulzer was accepted and the project got underway following the call clarifying the technical specifications.

Marcin Chojnacki, Regional Sales Manager for Sulzer, commented: “We created an extensive parts list for the new control panels and made certain that everything we needed was available from stock – we did not have any spare time to wait for back-orders. Using our preferred suppliers, we were able to place orders for immediate delivery to ensure our build process could start without delay.”

In this case, the customer requested a variable speed drive (VSD) for each pump, preferring this to a star-delta starter for this application. Having the information about the application enabled the Sulzer technicians to pre-program the VSDs with the required control profile.

The delivery date of December 21 was achieved, a full three weeks ahead of the customer’s expectations.

A representative from Ocean Point Terminals, explained: “Project timing is very important for us and Sulzer was able to quickly translate our request into a delivery. The specification and ordering process was seamless and the new panels have been installed successfully, enabling our expansion project to remain on track.”

Marcin concludes: “Our expertise in pumps and pumping applications ensures the best control solution for our customers. Thanks to our excellent supply chain and in-house design team, we were able to complete this project well ahead of the deadline.

Source: Sulzer Ltd.