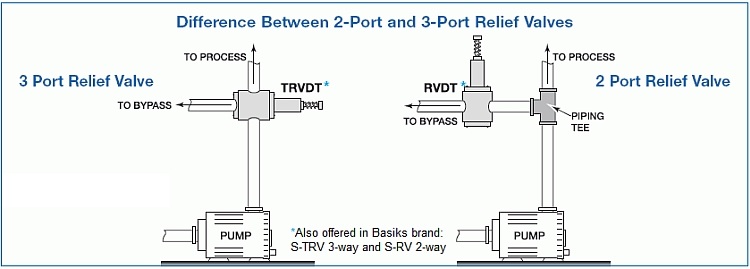

Plast-O-Matic: What, How, Where & Why of 2-Port vs. 3-Port Relief Valves

2-Port vs. 3-Port Relief Valves. (Image source: Plast-O-Matic Valves, Inc.)

- Preventing overpressure conditions in vessels and piping systems (relief valve).

- Providing by-pass flow relief to avoid pumping problems such as deadheading (pump bypass valve).

- Maintain backpressure in a piping system (backpressure regulator).

- Enhance pump performance by maintaining backpressure on the pump outlet (pump backpressure valve).

- Prevent gravity-induced siphoning through a pump, opening only when the pump is on (anti-siphon valve).

3-port designs, on the other hand, are generally limited to #1 and #2.

2-port relief valves require a piping tee for by-pass and relief applications, but not for backpressure or anti-siphon applications. Unlike three-port style valves which are placed directly in-line and cause a drop in both pressure and flow, a valve "teed" off the line usually offers the best system design and ease of maintenance.

In most relief and by-pass applications, 3-port valves do not perform as well as 2-port valves installed on a tee. No 3-port relief valve is suitable for use as a backpressure regulator or anti-siphon valve, and no 3-port relief valve will deliver the flow and performance of a Plast-O-Matic 2-port relief valve.

The illustration above shows the essential differences between 2-port and 3-port relief valves; note the advantage of piping convenience in the 3-port installation compared to the advantage of unhindered flow in the main pipeline shown in the 2-port installation.

Advantages of a 2-Port Design:

- Versatility. 2-port relief valve can also be used as a backpressure regulator and an anti-siphon valve; 3-port cannot.

- Choice of in-line or angle pattern provides a variety of piping design options.

- Flow capacity is far superior; 2-port valves provide less restriction and less deadleg.

Advantages of a 3-Port Design:

- Smaller "footprint" in a system.

- No need for additional piping tee.

- Easy replacement in existing systems using 3-port valve.

Plast-O-Matic offers the highest capacity backpressure/relief valve for both applications; Series RVDT 2-way and Series TRVDT 3-way. Because of the advantages of the 2-way valve, most sizes in PVC are available off-the-shelf. The TRVDT is available on special order. In addition to these high performance models, they offer economical options in our Basiks price/performance line.

Source: Plast-O-Matic Valves, Inc.