They are mainly used in installations requiring large flow rates, abnormally high working pressures (cast steel, S.G.iron) or special temperatures or pressures respectively. Their installation requires heavy foundations and extensive piping configurations. The high flow velocities within the pump body and the pump ports often require special noise attenuation measures.

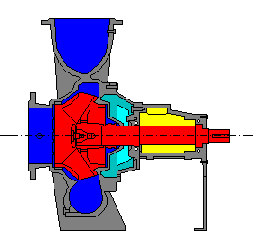

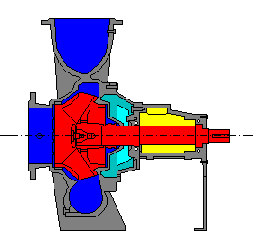

The following diagram depicts a sectional view of a flexibly-coupled end-suctionpump without motor, coupling and baseplate.

The pumps can be directly pipe mounted or, if necessary, be separately supported by foundations or brackets.

The high continuous temperature rating (up to 140°C) and the vibration-free operation on account of respectively shaped pump housings, impellers and drive motors are the decisive design features of this, especially for building services developed pump design. Low flow velocities through the housing as well at the pump ports make special noise attenuating measures (flexible connections) superfluous.

In building services, especially for pumps for heating and air-conditioning technology, the classification of the pump design according to the sealing (wetting of the motor) is widespread:

| Design |

Description |

| Glandless Pump |

Glandless pump with canned rotor motor |

| Glanded Pump |

Centrifugal pump with shaft seal |

In addition, the subdivision according to the type of installation or the arrangement of the drive is common:

- Monobloc with flange-mounted motor

- DIN-standards with motor and coupling on common baseplate