They transport the fluid through a star-shaped wheel into a channel next to the impeller. The delivery heads achieved are 5 to 15 times higher than those of radial impellers.

The pumps are self-priming. They are used in particular for the conveyance of liquid-gas mixtures (partial gas conveyance) and for special suction requirements.

The efficiency is comparatively low. Therefore, the power range is only up to about 4 kW.

Due to the narrow gaps, they are generally not suitable for conveying fluids with abrasive components.

They are mainly used in installations requiring large flow rates, abnormally high working pressures (cast steel, S.G.iron) or special temperatures or pressures respectively. Their installation requires heavy foundations and extensive piping configurations. The high flow velocities within the pump body and the pump ports often require special noise attenuation measures.

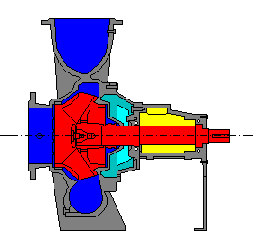

The following diagram depicts a sectional view of a flexibly-coupled end-suctionpump without motor, coupling and baseplate.

Liquid pumps are divided into centrifugal pumps and positive displacement pumps according to their operating principle. There are also special designs such as jet or mammoth pumps.

In a narrower sense, in contrast to blowers and compressors for gases and compressible media, pumps for incompressible media are referred to as liquid pumps. This means that the volume of the fluid remains approximately constant as the pressure increases. In practice, this also includes liquid mixtures with a low solid or gas content.

Depending on the direction of the energy flow, pumps belong to the working machines.