Pumping Without Air Inclusions

Air inclusions encountered during pumping of media pose, in many regards, a variety of problems. Pumps cannot reach their full capacity during suctioning, the motor is overloaded and foam formation complicates delivery. A venting valve from Schmalenberger provides help in this respect.

The ½ inch valve can be retrofitted and enables the rapid venting of air in the pump system. As a result, maximum pumping capacity is achieved again, rapidly and without complications, while additional foam formation in the pumped medium and dry running of the pump motor are prevented. The IPE valve was specially developed for SM series self-priming waste water pumps. In addition to relieving stress on the pump motor, the IPE valve primarily embodies economic advantages, as preventing performance losses saves energy.

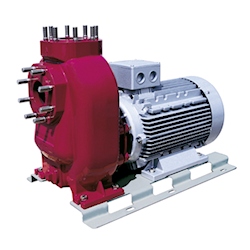

Schmalenberger offers self-priming sewage pumps for clean and polluted liquids or media with gaseous inclusions. Main fields of application: coolant supply, environmental protection technology, surface technic, water supply and -filtration. Special version with sealing chamber.

The SM serie is Schmalenbergers answer to the complex challenges faced in the customers process chain: delivery without mechanical comminution, no complex lifting equipment, self-priming where even zero levels and severely foaming fluids are involved, selectively available with a sealing chamber to protect the mechanical seal, as a dry installation with space-saving and compact installation. An extremely varied model range has made the SM extremely successful favourites in mechanical engineering. A variety of uses are possible: from small machine tools to heavy metal machining, from production involving metal machining to grinding, water jet cutting to recirculation pumps.

Areas of application

- Centralized lubrication system

- Process engineering

- Sewage engineering

- Draining, drainage

- Industrial technology

Areas of use

- Liquids with high air occlusion

- Strongly contaminated liquids

- Liquids which may also contain solid

- neutral media, such as alcalines, solvants, coolants, lubricants a.s.o

- Surface technique washing, cleaning, degreasing,phosphating, pickling

- Machine-tool industry environmental technology

- Filtration and recycling technology

- Recirculating for cooling lubricant

Picture: Schmalenberger

Source: Schmalenberger GmbH & Co. KG