New Standards in the Digitalization of Pumps and Their Usage

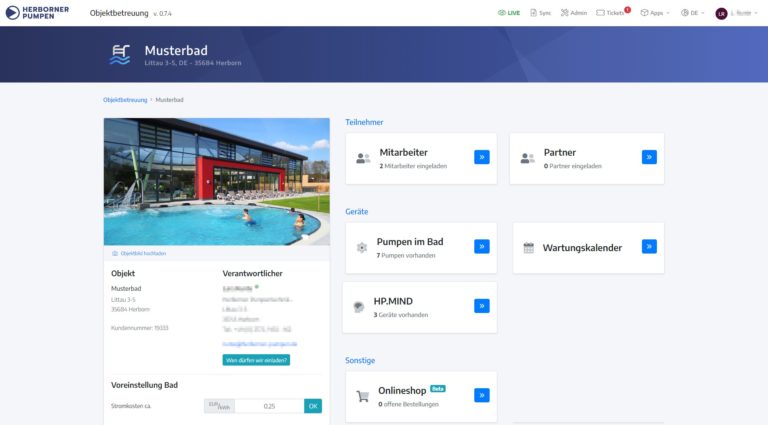

The smart online pump management system: Creating the future of swimming pools – now! (Image source: Herborner Pumpentechnik GmbH & Co KG)

Sascha Korupp, Technical Director of the company, has been working for some time with his team on making all documentation for pool pumps digital and easy to retrieve and supplement with additional useful tools. “We didn’t always have the tools available that we are able to use today,” Korupp said. “With this goal in mind, we have consistently followed the path of digitalization and have built a team of experts at an early stage that now provides us with the tools we need, while also interacting with all other interfaces such as service fitters, field service and customers in order to offer customers the best possible solution. For one thing, customers can now use digital tools that have been programmed for their market-specific requirements; for another, they are part of a continually growing community whose suggestions contribute to the constant optimization of the tools.”

The platform Herborner has created for the asset or object view of a pool's installed pumps is called HP.OBJECT. It is part of the HP.INTELLIGENCE digitalization strategy which includes, among others, the smart pump selection program PAHN AI and the pump controller HP.MIND, as well as the cloud solution HP.IOT. This allows pumps to be monitored and controlled in real time.

HP.OBJECT is setting new digital standards here. From the view of all Herborner pumps contained in the object, the customer has access to all digital documents. After logging in, they are taken directly to the desired documents, tools and operating instructions, which are always up to date. Technical changes are thus always included in the document in a matter of seconds – worldwide.

Many other options have been included in HP.OBJECT in order to more comprehensively support customers. The digital product passport also includes the data specifications for the pump in question as well as supplemental videos which simplify everyday handling of the pump. An additional view enables the pump profile to be retrieved as a digital characteristic diagram with the function of a true operating point illustration – including when speed is controlled by inverters. The true depiction of the pump characteristic curve presents the operator with options for operating point modification in order to run the pumps in a more energy efficient or conservative range. Of course, the designated field service representatives also provide support for matters of energy efficiency, already being able to address the issue on the digital level via the platform solution. As a result, the operator saves money and resources over time and reduces the probability of pump failure.

The HP.OBJECT calendar manages and digitally tracks the work of personnel without forgetting anything. It can be used to schedule maintenance work such as lubrication periods for bearing lubrication of the pumps or internal work in the area of plant engineering.

Operators can also easily update their plant if older pumps have been replaced over the course of time. In addition, the pumps can be structured and digitally compiled with respect to plant components. To this end, HP.OBJECT enables the grouping of installed pumps in order to provide a helpful overview of the installed pumps in individual pool areas or individual attractions. Of course, Herborner Pumpen is always available for ongoing support.

If spare parts or accessories are required, HP.OBJECT now also offers an integrated spare parts catalog with a corresponding online shop. The operator will thus be able to easily place orders around the clock in order to avoid the loss of time during order processing.

To generate informative added value, customers will additionally receive specialized information from current trade publications. This will provide added value far beyond topics relating to pumps.

HP.OBJECT provides the operator with a completely new view of their entire pool and individual plant components, as well as their respective pumps. A wide variety of tools and documents simplify handling of the pumps. The tool provides options for saving resources and simplifies processes such as spare parts procurement, for example. With HP.OBJECT, Herborner Pumpentechnik provides its customers with a platform solution which will be continually developed further in the coming years, with integration of customers and operators of plant technology.

The best part: HP.OBJECT is provided free of charge, just like the pump selection program PAHN AI.