New Highly Torsionally Flexible Coupling Series for Large Hydraulic Pumps

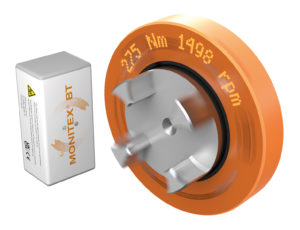

Image, left: SINULASTIC design A; picture, right: SINULASTIC design B. (Image source: KTR Systems GmbH)

In these fields of application the coupling series must feature particularly torsionally soft elasticity to uncouple the vibrations in the drive train generated by the diesel engine.

With SINULASTIC, designed as a disk coupling with radial load path, a highly torsionally flexible elastomer element is used between the external flange ring and the coupling hub damping the torsional vibrations that are generated in the system by the engine respectively shifting the operating range above the critical speed. Depending on the Shore hardness of the elastomer, torsion angles from 13° to 18° are reached.

Part of the challenges with the development of this extremely torsionally soft coupling were the calculation of the material behaviour with hyper elasticity as well as the selection of materials and the connection of various coupling elements, besides a focused modularity within the series. Based on FEM calculations and test runs in the KTR test field in Rheine, the design engineers decided with SINULASTIC type „A“ upon a sinusoidal outer contour of the elastomer disk engaging with a flange ring particularly tightly and positively, a shape that the name of the new series is derived from. Jochen Exner, Manager Innovation in KTR Thinktank in Hilden: „This design has proved to be perfect to first reach the necessary technical parameters in the smallest axial mounting space; second ensure the permanently solid connection of elastomer and flange ring with constantly alternating loads and speeds and third avoid cracking in the spline of the elastomer even with highly dynamic applications within the framework of the service life.

We found significant potentials here.“ The concept is supported by the implementation and production of the connection flange that is positively connected with the elastomer. In this case a welded component made of cold stamped sheet metal with a lasered, variably adaptable connection flange is concerned. Jochen Exner: „This highly dimensionally stable and light-weight design allows for a tailor-made contact gap, at the same time creating the precondition for high variety of adaptation for connecting the coupling to the flywheel. The consequently smooth contact surface has considerable advantages over renowned cast and thus rough surfaces of aluminium flanges.“

The SINULASTIC type „B“ does without the external positive fit between elastomer and flange; instead, a deep drawn angular ring is directly vulcanised to the elastomer disk on the outside. The plug-in capability of the coupling is obtained by the renowned BoWex spline on the inside of the elastomer. Jochen Exner further explains: „With this type we make use of the wide standard portfolio of BoWex hubs which enabled us to increase the maximum torque and displacement capability of the coupling element in the same mounting space. Even the use of the highly torsionally flexible disk element as an angular joint in the drive train is possible which allows for much simpler designs in a large number of applications.“

In total the SINULASTIC series comprises four types which are fully compatible with regard to connection geometry, mounting space and technical data in spite of their individual features so that an optimum solution is constantly available for the individual task of drive. During the launch phase the series is available in each nine sizes for nominal torques from 1,800 to 25,000 Nm and in various elastomer types.

Source: KTR Systems GmbH