Minimum Inlet Pressure

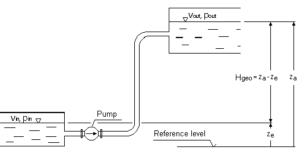

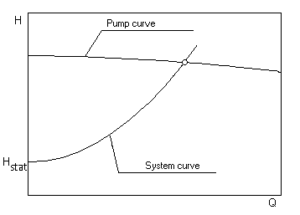

Pumps require, in order to ensure trouble-free operation, a minimum static inlet pressure at the pump suction port, which is generally termed the minimum available net positive suction head (NPSH).

This available inlet pressure decreases with the flow through the pump on account of the velocity change of the liquid in the suction section and the impeller. The critical location is the entry into the impeller suction neck. If the pressure then falls below the operating vapour pressure of the fluid, the fluid flashes into a vapour and forms bubbles.

The ensuing flow through the impeller leads to an hydraulic pressure build-up. Within this region the bubbles collapse or implode with a tremendous shock on the adjacent surfaces causing vibration and even destruction in the form of pitting or erosion. This process, termed Cavitation, is accompanied by low rumbling or sharp rattling noise with rising intensity as cavitation increases.

The pumping performance is also impaired as the pump is now handling a water/gas mixture. A minimum static inlet pressure must thus be maintained at the pump suction port in order to avoid cavitation.

The level of this required pressure depends on:

- the temperature of pumped liquid

- required net positive suction head HH (termed: NPSHrequired) corresponding to the pump duty point.

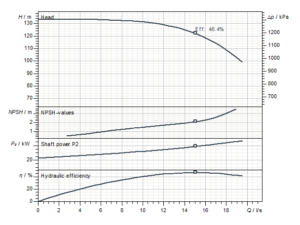

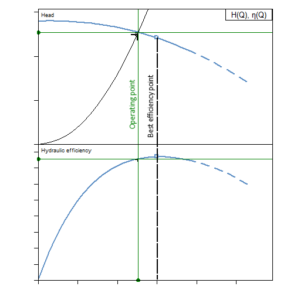

The required net positive suction head (HH or NPSHrequired) relates specifically to the pump and is normally depicted by pump manufacturers as an NPSH curve in the pump duty chart.

Generally there is a strong relationship with the pump speed. For constant pump types the following is true:

- High speed -> High NPSHrequired

- Low speed -> Low NPSHrequired

It is recommended practice to raise these levels by a safety margin of 0,5 m (1,6 ft) to compensate for possible variations on duty point calculations when selecting the pump. General standards allow a minimum level of cavitation at the determined NPSHrequired which:

- reduces the Pumping Head at the duty point by 3% or less

- does not cause any material deterioration, performance reduction or reduce service life.

Such acceptable levels of cavitation may however cause unacceptable noise.

To ensure best performance, it is common practice to load the NPSHavailable calculation with a safety margin of approx. +1 to +5 m (+3 to +15 ft), depending on speed and Duty Point of the pump.