ViscoTec Presents Extended Version of the Static-Dynamic Mixer

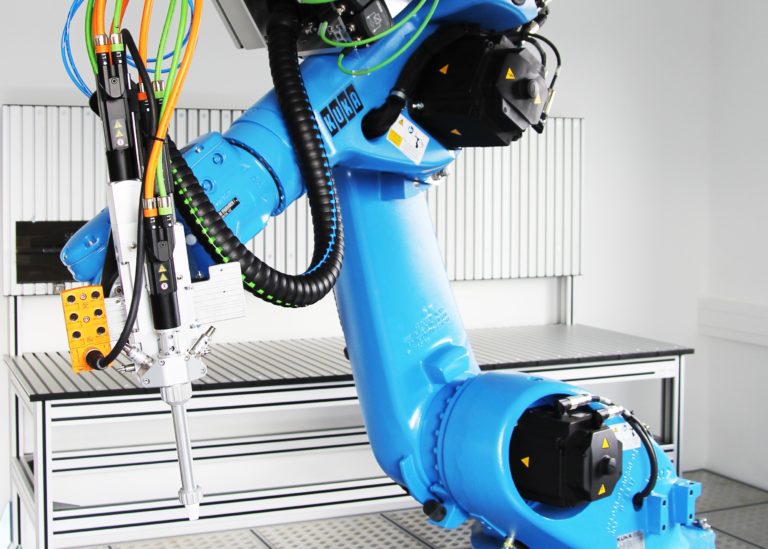

The static-dynamic mixer vipro-DUOMIX. (Image source: ViscoTec Pumpen- u. Dosiertechnik GmbH)

The extended version with optimized mixing blocks for low-viscosity, and high-viscosity materials on either side brings a further advantage: It is ideally suited for materials that are difficult to mix - with different or identical viscosities. A modular design with five different dispenser sizes per side allows complete flexibility, and a wide range of mixing ratios from 1:1 to 100:1.

The vipro-DUOMIX can be used for complex two-component applications in diverse industries such as automotive manufacturing, aerospace, or electronics. Irrelevant of whether it is for a dot dispensing, a bead application or for a potting application. Particularly in the production of aircrafts the static-dynamic mixer is used for honeycomb potting or for edge sealing. Special nozzles with adjustable bead width are available for this purpose.

A wide range of two-component materials based on e.g., polyether, epoxy resin, silicone or polyurethane can be dispensed in all areas of application. Due to the parallel alignment of the dispensers, and due to a weight-optimized design, the vipro-DUOMIX is very compact – ideal for assembly in robotic cells or for automated applications.

The advantages once more at a glance:

- Flow and back pressure optimized product channels avoid compression of the material to be dispensed.

- Setting of the desired mixing ratio by independent adjustment of the speed of either dispenser

- Dynamically adjustable mixing quality by adjusting the speed of the mixing elements

- Gentle handling of the dispensing material

- Density remains unchanged during the entire dispensing process

- Compact design due to parallel alignment of the dispensers

- Perfectly suited for low to high viscosity materials