Service Time Reduced to a Fraction with Sulzer’s New Shut-off Device for Agitators

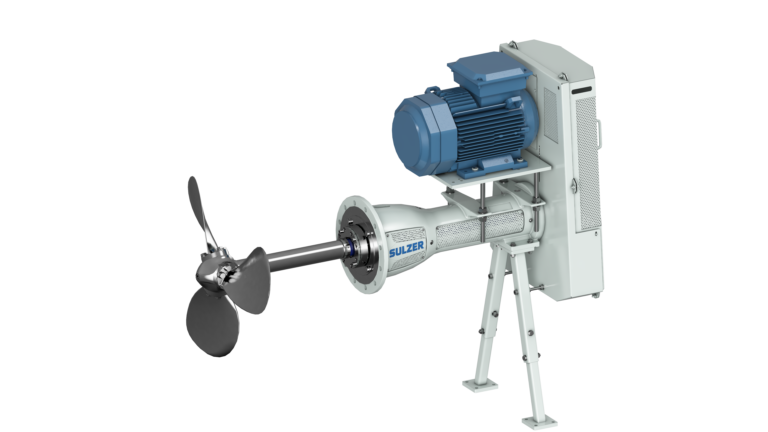

Salomix™ SSA with SOD shut-off device (Image source: Sulzer)

Innovative mechanical structure enables reliable operation

After shutting down the agitator, SOD is activated by pressure, which expands a rubber element that clamps around the shaft. The pressure can be applied with a simple hand pump, and either by air or water. There is no need to remove the shaft or unlock the bearings, which significantly speeds up the maintenance process. The simple structure also minimizes the chances of misuse.

SOD is designed for a longer seal lifetime. Outside maintenance periods, the large radial clearance between the shaft sleeve and SOD’s cartridge provides an open seal environment that prevents clogging and drying out. Especially with contaminated liquids and slurries this is a key feature in maximizing seal lifetime.

After extensive testing, the patented construction of SOD has proven to be extremely reliable. It enables a tight seal and works robustly even with impurities in the liquid. As a result, the device is especially suitable for paper pulp, wastewater, biofuels, metals, and mineral applications.

Versatile range suits most applications

SOD represents the latest in Sulzer’s continuous efforts to finalize its market-leading agitator selection. “In the past few years, we have developed the portfolio of our side-mounted agitators by combining our expertise with the customers’ needs, which has led to market leading hydraulics and a comprehensive agitator range packed with smart features. SOD is a good match with our objective to always serve our customers with innovative and reliable technology,” says Patrik Kolmodin, product manager of agitators at Sulzer.

SOD suits most industrial applications. It is globally available for all sizes of the side-mounted SALOMIX™ SSA agitators in either EPDM or FKM rubber. The devices can be combined with gland packings or split mechanical seals. They endure high temperatures up to 90˚C (195°F) and pressures up to 4 bars (58 psi).

Source: Sulzer Ltd.