Safe and Clean: Allweiler Pumps with Allseal

Screw pumps made by Allweiler AG are now available with a new opto-electronic module. Known as "Allseal”, this new product detects wear of the mechanical seal as soon as it begins and immediately warns the operator of any leaks.

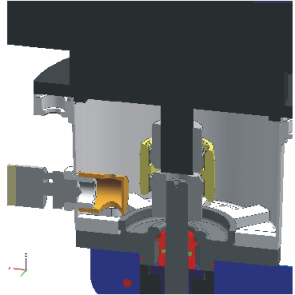

The coupling bracket captures the standard leak coming out of the pump. The opto-electronic sensor is located in the wall of the bracket. If liquid escapes and reaches this sensor, "Allseal" will immediately react to this situation with the proper steps.

The pump can then be automatically switched off and pumping tasks switched over to a secondary unit.

Plant operators recognize pumps as the heart of their systems and value them accordingly. Collaborating with its customers, Allweiler has developed a new series of modules designed to preserve value and reduce costs. By doing so, this German-based pump manufacturer is fulfilling a current need and following up on its customers desire for increased safety.

“Allseal Technology” is available on Allweiler’s vertically installed screw pumps and eliminates unpleasant surprises caused by sudden or gradual leaks. The new monitoring and control system protects the pump from damages, extends its service life, and prevents expensive interruptions of the pumping process. Allseal is also an ideal solution for pump operators who must comply with special environmental regulations or other requirements such as SOLAS directives for flammable and explosive liquids.

The opto-electronic system immediately detects if a liquid escapes around the mechanical seal. Unusual leaks trigger acoustic and visual warning signals. These signals may be integrated into a centralised control system or forwarded to a monitoring station. Depending on the specific installation, the leaking pump may be switched off automatically and operation simultaneously switched over to a reserve unit.

"Allseal” is available on almost all Allweiler screw pumps. Customers can request to have new pumps equipped immediately with Allseal technology. But existing customers can also have their pumps retrofitted with Allseal. Dr. Michael Matros, Executive Board member at Allweiler AG, described Allseal at its introduction: “This new technology makes Allweiler the only pump manufacturer to offer a modular sealing concept. The customer can now choose between conventional mechanical seals, the new Allseal version with leak detection, and hermetically sealed pumps with magnetic drive.”

About Allweiler

Founded in 1860, Allweiler AG is the oldest German pump manufacturer and the European market and technology leader for centrifugal, propeller, screw, progressing-cavity, cogwheel, rotary lobe, macerators, and peristaltic pumps. Allweiler AG owns a foundry and produces its own stators. It manufactures ready-to-use fuel and lube-oil skids and rinsing-water facilities. Allweiler AG has its main German headquarters in Radolfzell on Lake Constance as well as a major production site in Bottrop, Germany. Allweiler AG has been part of Colfax Corporation since 1998.

About Colfax Corporation

Colfax Corporation is a global leader in critical fluid-handling solutions, including the manufacture of positive displacement industrial pumps and valves used in global oil & gas, power generation, marine, naval and a variety of other industrial applications. Key product brands include Allweiler, Fairmount Automation, Houttuin, Imo, LSC, Portland Valve, Tushaco, Warren and Zenith. Colfax is traded on the NYSE under the ticker “CFX.”

Source: ALLWEILER GmbH