Refinery Pump Retrofit Boosts Output

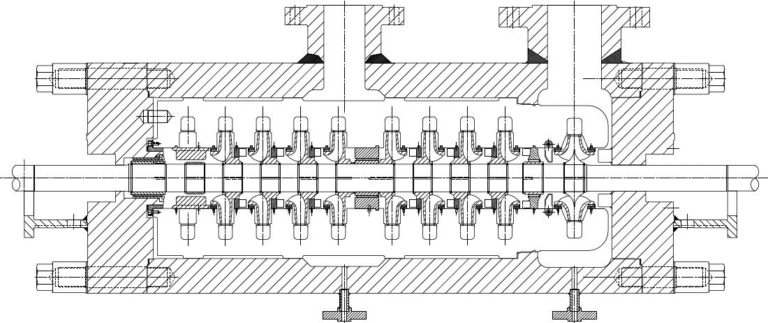

Cross section of pump barrel and internals, showing reduction from 10 / 9 stages (Image Source: Sulzer)

Matt Kinney, Hydraulic Retrofit Specialist at Sulzer, examines one example in Texas where a retrofit project enabled new targets to be met.

Changes in national regulations over the past few years have seen the demand for ultra-low sulfur diesel (ULSD) increase significantly. Consequently, refineries have had to adapt their processes and find innovative solutions to deliver increased capacity. In Texas, the situation led to a refinery reaching out to Sulzer’s Odessa Service Center to look at possible solutions.

The project revolved around two BB5, 10-stage diesel charge pumps, which needed to increase delivery rates by over 47%. The American Petroleum Institute (API) BB5 is a barrel pump that encloses a multi-stage axially split inner bundle with an opposed impeller configuration.

Being that the pressure boundary is radially split, these pumps are typically designed for high-temperature and/or high-pressure applications. With the capability of handling pressures and temperatures up to 6’250 psi (431 bar) and 800 °F (427 °C) respectively, the API BB5 is an excellent pump selection for applications such as water injection, oil export, boiler feed, and charge service.

Establishing new goals

Originally installed in 2006, the pumps had a rated point of 1’110 gpm (252 m3/hr) @ 4’014 ft (1’223 m). However, with the change in ULSD demand, the reliability engineers at the refinery were interested in a capacity increase to 1’628 gpm (370 m3/hr) @ 3’450 ft (1’052 m). The goal for Sulzer was to find the most economical and timely solution to meet the customer’s needs.

Under these circumstances, there were three possible options. Firstly, purchase a new pump that meets the new capacity requirements; alternatively, modify or re-rate the original pumps or, operate both of the existing pumps in parallel at 100% rated capacity (depending on the customer system curve).

Each of these options has its own advantages and disadvantages. For example, parallel operation would clearly be the least costly to achieve the increase in flow. However, the lack of system redundancy in the event of a failure is risky and can often be very costly in terms of lost production.

A new pump selection to fit the application could be advantageous with regards to efficiency but long lead times, the cost to reroute pipework, and baseplate/foundation modifications may make this option less attractive. There was really no downside to re-rating the pumps other than the desired performance may not always be achievable in the given frame size. However, if feasible, re-rating is often faster and more economical.

Design simplicity

According to the criticality of this service for the overall success of the refinery, the possibility of re-rating was of great interest. To support the customer, Sulzer engineers conducted a thorough feasibility study, both hydraulically and mechanically, to determine whether the goal was possible.

A specific speed (Ns) based search through Sulzer’s vast hydraulic database revealed an existing, proven design that would meet the customer’s needs – provided the impellers were able to physically fit, and the inner-case volute nozzle areas were able to be increased enough to allow the impeller to meet as-designed performance. A review of the volute development drawings provided confidence that both items could be fulfilled.

Sulzer elected to keep the approach as simple as possible so as to minimize the overall project time. This was achieved by selecting an existing standard impeller hydraulic design that was suitable for the desired performance and had been proven by at least two factory tests. Furthermore, the company ensured that the case modifications could be made to fit the new impeller and confirmed the nozzle area could be increased sufficiently to mimic the reference pump performance.

Ideally, Sulzer would have performed a factory test after completing this work, but unfortunately, the project’s timeline did not make this possible, given the agreed deadline. Therefore, it was important that the proposed upgrade was supported by internal, empirical data and experience to provide confidence in the accuracy of the proposed design changes. It was necessary that the predicted impeller trim was calculated correctly at the first attempt.

Optimized solution

With a massive array of impeller hydraulic designs available, Sulzer engineers were able to select an existing design that would meet the new head and capacity required for the application.

A mechanical cutback was done to achieve both an increase in nozzle area and lip diameter. Based on empirical data, the increase in nozzle area would allow the new impeller selection to runout to the new design point. The increase in volute lip diameter enabled the designers to achieve sufficient lip clearance. This, and the fact that the cutback was ‘angled’, helped with the reduction of vane pass pulsations and overall vibration amplitudes.

The outlet vanes of the impeller were underfiled to increase the outlet area between vanes (OABV) and help flatten the performance curve. This also pushed the best efficiency point (BEP) to achieve higher flows.

The design process highlighted the fact that the new performance level did not require all 10 stages. One stage was removed so that the impeller trim could be near-full diameter. This benefitted both the efficiency and the BEP location for the pump. With the stage reduction, the effect on axial thrust direction and magnitude was analyzed; the internal bushings were resized to ensure the axial load was acceptable for the thrust bearing.

Surpassing the challenges

With a major re-rate such as this, it can be rather difficult to fit a new, relatively large, high-capacity impeller within the existing volute. This is because multi-stage pumps, such as this, are designed with the shortest possible stage spacing to limit overall pump length.

Fortunately, the pumps in this example were originally equipped with a relatively low-flow rotor, compared to its frame size, which offered more room to work. In order to accommodate the increased impeller outlet width, the volute side walls required widening or “slabbing” to ensure adequate side-room clearance, which is extremely important to centrifugal pumps.

In addition, the inner-case line bore diameter was increased to accommodate the larger impeller eye diameter. The bore was increased to the maximum allowable value, while maintaining enough wall thickness between it and the waterways as well as maintaining structural integrity of the inner bundle.

The increased pump performance required more power than the original 1’250 hp (932 kW) motor could deliver, so a new motor was required to meet this demand. However, no baseplate modifications were required as the frame size for the higher rated motor remained the same.

The net positive suction head required (NPSHr) had increased with the new selected suction impeller. However, this was not a problem as the net positive suction head available (NPSHa) was adequate.

Delivering advantages

The decision to re-rate the existing pumps, rather than buying new, was highly advantageous for the customer in this case. The re-rating project was more economical, especially since the outer barrel alone is a very high-priced component.

The re-rate required no changes to the footprint of the existing pump, saving valuable time in completing the project. If a new pump had been specified, baseplate modifications and the rerouting of suction and discharge pipework would have been required.

The hydraulic modifications were all confined to the inner-bundle, allowing the outer-barrel to remain piped up in the refinery. This had a significantly positive effect on the overall delivery time for the project and the much shorter completion date proved very attractive to the customer.

Project outcome

Once complete, the pump was reinstalled and commissioned. Due to the high levels of confidence in the design and engineering, the performance testing was conducted on site. The pump surpassed the original flow and head requirements, which exceeded the customer’s expectations. Both the vibration levels and bearing temperatures were well within the acceptable limits.

This project was a major success and the customer was pleased with the overall outcome. The final major benefit was that the payback period for the cost of this project was achieved in the very short time of just 35 days.

Source: Sulzer Ltd.