Prefabricated Pumping Stations to Help the Philippine’s Flood and Wastewater Management Efforts

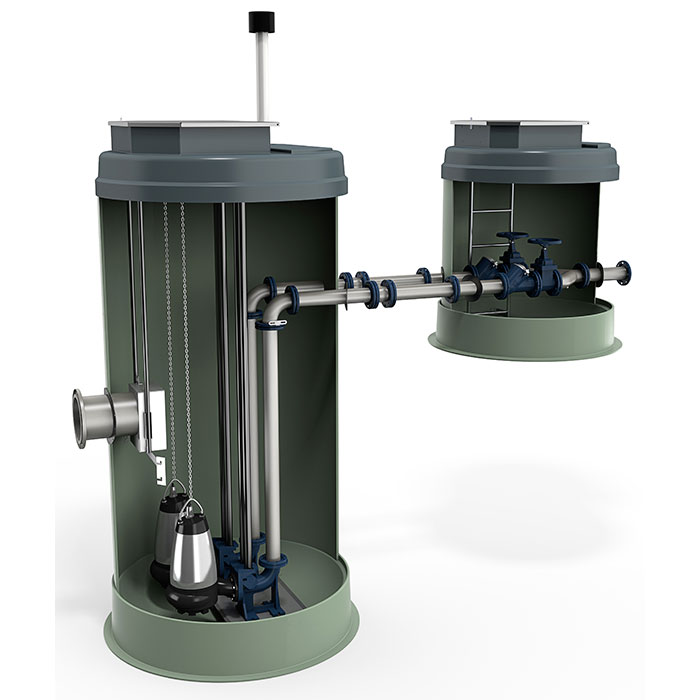

PPS Design (Image source: Grundfos)

With the growth of the economy and rapid urbanization in the Philippines, the country is facing significant challenges in terms of water and sanitation. Around seven million rely on unsafe and unsustainable water sources and 24 million lack access to improved sanitation*. As the government of Philippines has geared up to address the issues of universal water and sanitation services coverage by 2028, reliable and intelligent technology will play a critical role in enabling this transformation. The PPS is a sustainable turn-key solution that reduces both installation time, commissioning costs and the space requirement substantially.

The PPS is designed to be energy efficient and operate reliably in the long run. Traditional pumping stations are made of concrete casted on-site, which means that it is susceptible to corrosion and leakage over time. With PPS being made of hard-wearing plastic, its greater durability paired with an advanced control system means optimised operations, and in turn greater energy savings.

Jonathan Breton, General Manager, Grundfos Philippines said, “The PPS also only requires a short construction timeframe. Compared to traditional pumping stations, PPS is produced in the Grundfos factory and sent to the site as a complete package, making installation easier and usually completed within 24 hours. This reduces installation time by as much as 80%, ensuring minimal disruption to people and infrastructure. With the lockdown due to the COVID-19 pandemic, the PPS solution will significantly help complete the installation faster and avoid potential additional costs and delays.”

In addition to flood control, another key application for PPS is in wastewater management. Playing a key role in the wastewater management process, pumping stations are designed to collect and transport wastewater, and PPS’ high durability ensures minimal disruption to any water system. This solution can play a key role in urban as well as remote areas and create a reliable decentralized wastewater management system.

The PPS is an ideal solution for wastewater management at tourist destinations and hotels. Grundfos has recently installed its first PPS solution at Lio, a tourism estate whose water and wastewater facilities are owned and operated by Manila Water’s Business Unit, Estate Water (EW), which is located in El Nido, Palawan.

Commenting on why EW opted for Grundfos’ solution, Benson Cruz, Technical Services Head, said “Lio constantly raises the bar for sustainable tourism. Therefore our obvious choice was Grundfos’ Prefabricated Pumping Stations as it helps helped us decrease not only our overall environmental footprint but the project cost as well. It also has a smaller footprint - the original lift station design was sized at 60 sq meters and Grundfos’ PPS and controller has taken only 36 sq meters.”

Commenting on the efficiency of PPS, Jon Remulla, WU Segment Manager, Grundfos Philippines said, “As the PPS features the Variable Frequency Drive and dedicated controls, it also helps reduce the power consumption and energy costs by 30% and 35% respectively.”

With over 40 years’ experience globally, Grundfos’ PPS solution has demonstrated its quality and effectiveness in several projects for various applications in Southeast Asia. Outside of Southeast Asia, China has over a thousand installations of PPS to address the high demand resulting from the country’s fast-growing urbanisation, for various applications including sewage pumping, drainage and flood control.

* Source: www.water.org

Source: Grundfos Holding A/S