Energy-Efficient and Clog-Resistant Pumping of Raw Sewage

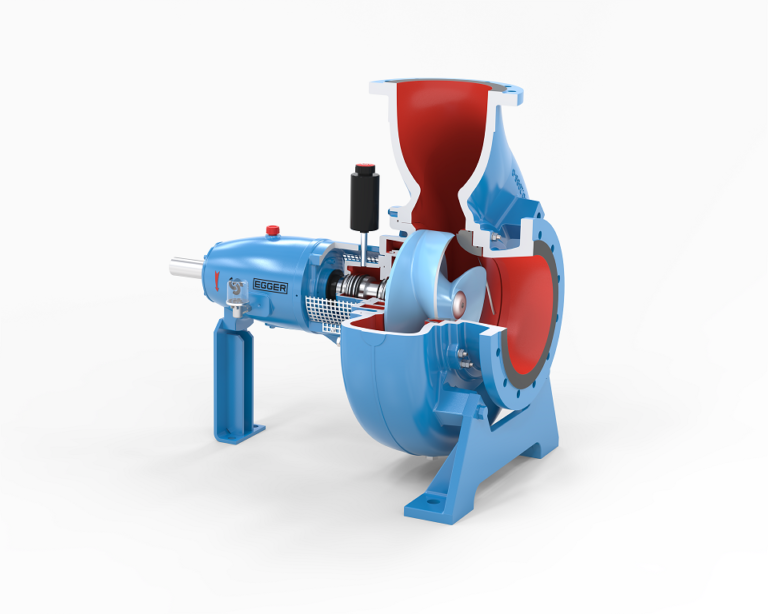

Energy-efficient and clog-resistant pumping of raw sewage with the new EOA pump series. (Image source: Emile Egger & Cie SA)

The new EOA pump series was developed in order to achieve higher flow rates compared to the fully recessed vortex pumps. This is based on a 2-bladed semi-open radial impeller.

Currently, a wide variety of pumping stations and wastewater treatment plants in Switzerland and Germany are equipped with these pumps. A clog-resistant pump alone is no longer sufficient to meet today's requirements; it must also have a corresponding energy efficiency. In order to continue developing and improving this, Egger installed a completely newly developed EOA impeller of size EOA 8-250 for field testing at the beginning of 2020. The impeller was previously tested at the Technical University (TU) of Berlin on a test stand with a standardized wastewater.

Already the first measurements after installation on the wastewater plant showed that the very good values of the measured values from the TU-Berlin were confirmed in practice. Efficiency improvements with raw sewage of up to 10 percentage points compared to the original version could be proven.

A good indication value is the effective energy requirement to pump 1m³ of raw wastewater 1m high [kWh/m³*m]. This value includes all power losses of pump, motor as well as frequency converter. The theoretical value (individual efficiencies 100%) is 2,725 Wh/m³*m. The optimum achievable in practice with raw sewage is 4 Wh/m³*m.

A proven test to prove the clogging resistance of pumps is an one-hour run. Here, the pump is operated at constant speed for one hour and the flow rate is measured. The flow rate must remain constant over time. This shows that the incoming fibers are conveyed 100 percent. Thus, the pump is clog-free.

The resistance to clogging has been significantly improved. This can also be judged by the required torque of the pump. In the same period, there was 4.7 times less torque-related pump shutdown than was the case with the first impeller generation. Under the same operating conditions of a single-channel wastewater pump with a spiral impeller, the value was even 5.8.

In summary, it can be said that with the development of the new EOA impeller, an energy-efficient and clog-resistant pump has been realized that is close to the optimum. Thus, the company is prepared for future requirements by a planned eco-design directive for wastewater pumps of the EU.

Source: Emile Egger & Cie SA