High Gas Contents in Liquid Media are no Problem for Egger Pumps

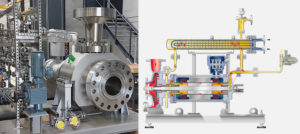

The pump for Eastman on the manufacturer’s pump test bench. (Image source: Emile Egger & Cie SA)

At first, a horizontal ANSI pump was installed which caused many failures, mechanical seal issues and misalignments due to thermal dilation. It was then replaced by an API vertical inline pump, which also initially had some design issues, which were resolved with the original vendor during the warranty period. However, the problem of gas-related failure persisted and continued to occur at irregular intervals. The gas load was clearly too high for this type of pump with a closed impeller.

System design was optimized

It was a challenge that had to be faced. Eastman had already installed a pump from the manufacturer in its Sauget plant in Illinois in the past and one of the chemical company’s pump specialists remembered the manufacturer Egger’s capabilities with multiphase fluids. The two companies worked together since February 2019 to optimize the system’s overall design, at the Kingsport site, including suction pressure, flow, head, gas concentration, gas composition and piping-sections and arrangement.

Special semi-open impeller also conveys multiphase liquids

The final solution from Egger was an API OH2 style horizontal pump, using Egger’s special semi-open impeller, suitable for three-phase liquids’ services (liquids, solids and gases).This special pump hydraulic design allows, in certain operating conditions, up to 25% entrained gas by volume in the liquid without affecting the pump’s efficiency.

The complete case study and engineering were managed within a month, and the pump delivered from Switzerland to the US job site within three months.

Since its installation in the plant, the pump is performing flawlessly with no interruption, loss of production or maintenance costs. The operator is satisfied. The “return on investment” is also remarkable: excluding installation cost, the entire order (a complete pump system, a spare unit and spare parts set) took only 17 days.

Source: Emile Egger & Cie SA