The mechanical power requirement of a centrifugal pump (shaft power) is directly proportional to the density of the pumped medium.

P 2 ~ ρ

P 2 = shaft power

ρ = density of the pumped medium

In contrast, the throttle curve of the pump H (Q) and the efficiency η (Q) are independent of the density.

These relationships are automatically taken into account by the pump selection software.

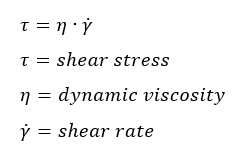

Newtonian fluids, at laminar flow, create shear tension and pressure super-imposed normal tensions which are proportional to the deformation velocity, the proportionality factor being the absolute viscosity.

The kinematic viscosity is defined as:

The viscosity depends on temperature and pressure, whereby pressure dependency of fluids is of negligibly small characteristics.

Viscosity of non-Newtonian fluids can moreover be time-related (thixotropic or rheopexic flow characteristics); its characteristics then becoming undefined.

The viscosity of a medium has an influence on both the system curve and the pump performance curve. For centrifugal pumps, the pump curves are converted in practice at a kinematic viscosity of more than 10 mm²/s.

It is, on one-dimensional flow:, physically defined as:

Of Newtonian fluid characteristics are e.g. the following:

- water

- oils

- gases

- mercury

- alcohol

- petrol

If it is not known whether a fluid is of Newtonian flow characteristics or not, it should be laboratory-tested.

The maximum and minimum temperatures of the pumped medium are of particular importance for the design of the pump. They are taken into account in the selection of materials and seals and, if necessary, in a media-material resistance test.

The fluid properties (density, viscosity) change with the temperature. The power requirement of the pump is directly proportional to the density. Therefore, the temperature must be taken into account from the operating range with the maximum density. Furthermore, for viscous media (ν > 10 mm²/s), the shape of the pump performance curve must be converted.

The kinematic viscosity is defined as:

The kinematic viscosity is defined as:

The viscosity depends on temperature and pressure, whereby pressure dependency of fluids is of negligibly small characteristics.

Viscosity of non-Newtonian fluids can moreover be time-related (thixotropic or rheopexic flow characteristics); its characteristics then becoming undefined.

The viscosity of a medium has an influence on both the system curve and the pump performance curve. For centrifugal pumps, the pump curves are converted in practice at a kinematic viscosity of more than 10 mm²/s.

The viscosity depends on temperature and pressure, whereby pressure dependency of fluids is of negligibly small characteristics.

Viscosity of non-Newtonian fluids can moreover be time-related (thixotropic or rheopexic flow characteristics); its characteristics then becoming undefined.

The viscosity of a medium has an influence on both the system curve and the pump performance curve. For centrifugal pumps, the pump curves are converted in practice at a kinematic viscosity of more than 10 mm²/s.  Of Newtonian fluid characteristics are e.g. the following:

Of Newtonian fluid characteristics are e.g. the following: