Thermal Oil Pumps for Medical Glove Production Line

High level cooperation between the application team in Germany and the sales team in China resulted in extremely quick customer response time and a delivery time of only 10 weeks, considerably shorter than average.

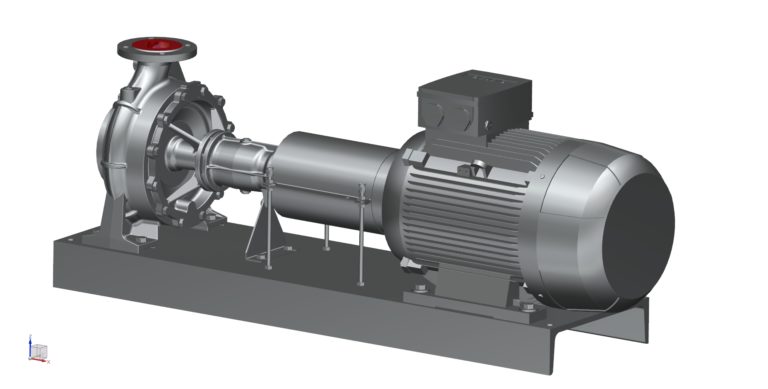

At an operating temperature of 280°C and almost atmospheric inlet pressure, the application requires a flow rate of 900 square meters per hour (m3/h) at 55 meters head. The NTT pump’s compact design enables it to operate at 1800 revolutions per minute (rpm), which is necessary to achieve the required flow rate.

Specially designed for thermal oil applications, the NTT pumps can handle high temperature and avoid thermal expansion problems during heat up and cool down phases. The mechanical seals are designed to avoid dangerous spillage of hot oil during normal operation or in the event of seal failures. High temperature anti-friction bearings ensure nearly maintenance free operation.

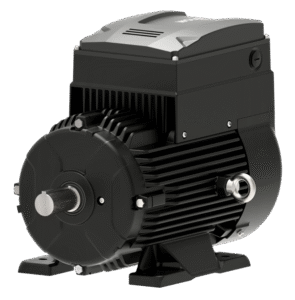

To control the pump speed, the pumps are equipped with a VFD to provide the electrical power at the required frequency to the 4-pole induction-motor. The frequency converter also ensures a soft start of the motor without the typical high current peaks typically experienced with direct on-line (DOL) pump starts. The frequency converter allows speed and performance adjustments for optimized process control, which will ensure a sensible temperature control of the heat transfer system. Using modern VFDs will ensure the pump always operates at the best possible operating point. It will also result in overall energy savings, typically 10 percent or more.

Source: CIRCOR International, Inc.