Saving Water in the Process of Brewing

Vacuum pumps within the brewing and bottling process are often far too greedy where water is concerned. When challenged with this imposition, Shaun Hampson gave his view from the Global vacuum brand of Sterling-SIHI.

Brewing processes, are actually quite demanding, which takes away some of the simplicity associated with the selection process. Foaming and product carry-over are common-place in such a process that often attracts a sanitary/hygienic classification. When process efficiency is added to the equation, then the criteria issued to the vacuum equipment suppliers surrounds:

- 30mbara - 1014mbara pressures

- Tolerant to foaming and liquid carry-over

- Highly reliable

- Efficient, and

- NO water consumption

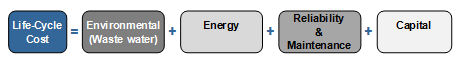

So, is there a real solution? Ultimately, the answer to this question lies with System Life-Cycle assessment following the common theme:

Generally, it is energy and waste that feature heavily in the total costs of ownership (and operation). Consequently, it is these aspects which ought to be at the centre of all brew-house, and bottling vacuum. Although this may seem obvious, the reality is sometimes different when brewers are faced with multiple equipment suppliers, each offering varying technologies at a broad range of prices.

Ejectors, eductors, liquid-ring vacuum, lobular-roots, totally dry vacuum, and other products are only the start of product choice. Their integration together with vital ancillaries makes all the difference to operational performance alongside reliability, waste, and energy efficiency. For instance, basic separator design based on operational experience can have a dramatic influence on water saving.

For almost 100 years, SIHI have been developing, manufacturing, and supplying the spectrum of vacuum and centrifugal pump equipment destined for some of the World’s biggest breweries, distilleries, and contract bottling sites.