Pumping Peanut Butter Made Easy Using Watson-Marlow´s MasoSine SPS200

Faced with a failing progressive cavity pump when trying to transfer peanut butter from the grinder to a holding tank, a reputable food plant in Pretoria, South Africa, has found a solution in a MasoSine SPS200 process pump from Watson-Marlow Fluid Technology Group.

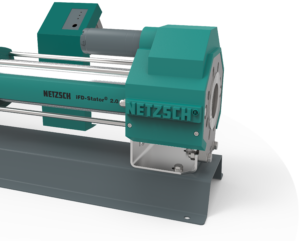

Pumping peanut butter made easy using MasoSine SPS200 (Image: Watson Marlow)

The peanut butter manufacturer was advised to consider MasoSine technology by the grinder manufacturer, and a SPS200 was duly installed in April 2014. The pump was immediately set to work pumping 250,000 cP viscosity peanut butter at a rate of 1000 l/hr (85C, against ±9 bar).

Product integrity

Selected, among numerous other factors, for its viscous pumping ability, the MasoSine SPS200 features a unique sinusoidal rotor that delivers a lower shear, gentle pumping action that safely transfers delicate products without risk of degradation. This is in contrast to the PC pump deployed previously, which battled to pump the high viscosity of peanut butter. Furthermore, dry running due to inconsistent feed between the grinder and the hopper would lead to reduced suction.

MasoSine SPS pumps are suitable for a multitude of applications up to 15 bar pressure and 99,000 l/hr flow rate. Importantly, products with viscosities up to 8 million cP can be transferred with powerful suction.

With this in mind, SPS pumps are able to deliver a constant feed of whole foods, meats, confectionary, dairy products and concentrates. Capable of handling soft solids up to 60mm, MasoSine pumps achieve high product quality and improved yield rates for food processing customers.

More uptime, fewer costs

To date, the Pretoria peanut butter plant reports that the MasoSine SPS200 has been pumping successfully with minimum downtime. In fact, the pump has offered considerable savings over the maintenance costs encountered previously with the progressive cavity pump. This is due to the pump’s simple design, with one shaft, one rotor, one seal and no timing gears.

The upshot is that maintenance and cleaning of the SPS200 takes just minutes and can be performed in-situ by a line operative (or by a CIP process, if required). Conversely, due to the design of the PC pump, maintenance took longer than the MasoSine technology and was also more expensive, leading to unacceptable levels of downtime.

The SPS200 now runs intermittently to pump circa 5 tons of peanut butter to the holding tank every day.