Plast-o-matic: Calibration Columns for Measuring and Verification of Pump Flow Rates

Plast-o-matic: Calibration Columns for Measuring and Verification of Pump Flow Rates (Image source: Plast-O-Matic Valves, Inc.)

Installation & Requirements

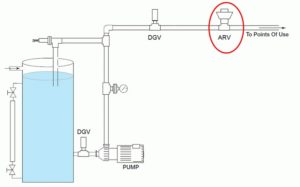

The calibration column should be installed on the inlet side of the pump or feed unit to be checked. It must be mounted in a vertical position, below the level of the tank liquid so that the column will fill when a valve is opened.

Two ball valves are required, installed in the locations shown in the diagram above. Ball valves are recommended because they offer minimal flow resistance, and they can be opened and closed quickly.

Notice in the diagram that an overflow or return line connection is installed from the top of the calibration column back to the supply tank. The calibration column has to be vented to the atmosphere when in use.

Finally, a stop watch or other timing device is needed to measure time during the test.

Measurement Procedure

1. Open valve A and start the pump or feed system. While the pump is running under normal conditions, open valve B and the calibration column should begin to fill with fluid. When the liquid level reaches the zero mark on the calibration column, close valve A and start counting seconds.

1A. If the column doesn't fill, turn off the pump with valves A and B open and use tank head pressure to fill the calibration column with liquid to the zero mark on the column and then close valve B. Start the pump. Once the pump is running under normal conditions, close valve A, open valve B and start counting seconds.

2. Time the liquid consumption of the pump for 60 seconds and record the volume pumped in either milliliters/minutes or US gallons/hour from the scale on the calibration column. (Plast-O-Matic calibration columns give a direct reading of the liquid pumped without any calculation.)

If it is difficult to get the fluid level to zero, timing can be started anywhere on the scale as long as the start level is recorded and subtracted from the final volume when the 60 second test period is complete.

3. At the end of the 1 minute test period, valve A can be opened to let the system function normally. The supply valve (valve A) should always be open when the pump is running (except while the test is being done) to prevent running the pump dry.

If the pump requires more than the capacity of the calibration column, a 30 second time period can be used but the volume measured from the scale on the calibration column must be multiplied by 2 for mL/min or GAL/hour.

If the pump uses a relatively small volume from the calibration column, a 2 or 3 minute time period can be used for more accurate readings but the final volume recorded will have to be divided by 2 or 3 respectively to determine mL/min or GAL/hour.

After the Test

When not in use, the calibration column can be used as a tank level indicator or drained by temporarily closing valve A with the pump running until all the liquid is pulled from the column line. If this is done, be sure to reopen valve A so the pump does not run dry.

Plast-O-Matic thermoplastic calibration columns are designed for precise, efficient testing with a variety of installation options:

- 100 mL to 10000 mL range of cylinder volumes available

- Exclusive UV-Resistant compounds resist fading & discoloration

- No metal components used in construction

- Highly visible/high contrast graduations

- Graduations have clear Mylar overlay for added protection in harsh chemical environments; label resists shrinkage and temperature damage.

- Long :60 second test period provides greater accuracy

- No calculations required for standard :60 test

- Removable cap option facilitates cleaning

Lifetime Guarantee: If you can't read it due to graduation label failure or column discoloration, simply send it back and Plast-O-Matic will repair or replace free, as long as the process liquid is compatible with PVC.

Source: Plast-O-Matic Valves, Inc.