Pilot Solenoid Valves Provide pH Control Despite High Backpressure

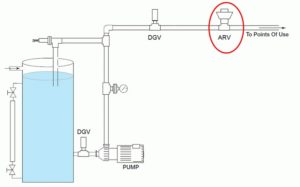

The Plast-O-Matic Pilot Solenoid Valve will open against high backpressures as long as a 5 PSI differential is maintained. The slower-opening piloted design is also ideal for preventing water hammer in many applications. (Image source: Plast-O-Matic Valves, Inc.)

The system relies on a few surface water sources, supplemented by some wells, so the pH varies.

To compensate for the fluctuation, a pair of 4,000 gallon tanks with a series of metering pumps and analyzers allow the caustic soda to be diluted when the water supply is closer to neutral. It may start at full strength, then go to 50% strength or less as required.

Backpressure concerns

The system design called for precise dosing into the pipeline from a pair of valves controlled by pH sensors upstream and downstream of the treatment point. The 30 PSI backpressure created by the city water main was a primary concern. The valves would have to open and close accurately against the high backpressure, and resist corrosion from the sodium hydroxide.

Overcoming the corrosion problem was relatively simple; thermoplastics would provide significantly better performance than metals. Of the common plastic valve materials, polyvinylchloride (PVC) was selected for its compatibility and relatively low cost. At that point, the possibilities covered a wide range of valve styles and actuation package combinations.

For speed and dosing accuracy, solenoid valves were the most likely candidates. The main pipeline, however, posed a problem since most standard 1″ pipe size PVC solenoid valves cannot actuate against 30 PSI backpressure and deliver a high flow rate.

Pilot design considerations

While searching for a solution, Bremerton Public Works contacted Plast-O-Matic Valves, Inc. of Cedar Grove, New Jersey. Plast-O-Matic, one of the longest established plastic valve manufacturers, suggested a solenoid valve with a “pilot” orifice. Known commonly as a “pilot-operated” solenoid valve, it uses a standard sized coil to first open and close against a small amount of flow. The line pressure, in turn, is used to actuate a much larger main orifice.

The pilot design is slightly slower than a direct-acting solenoid valve, but is able to provide excellent flow capacity with relatively high pressure. The split-second hesitation inherent to the pilot provides the added benefit of virtually eliminating the water hammer that an instantaneous solenoid valve might cause.

The valve specified, Series PS from Plast-O-Matic, offers flow capacity from 5.2 Cv to 80 Cv depending on size. The design provides an inlet pressure rating to 140 PSI and backpressure to 70 PSI. A pressure differential of 5 PSI is required for the valve to operate properly. In the Bremerton installation, a 1″ valve was specified, which provides a Cv of 9.5. The Series PS also provides a number of key safety features to the public works team. It provides a patented “Fail-Dry” safety vent, which allows the valve to continue operation in the event of a primary seal failure. The PS also has a PTFE bellows dynamic seal, offering the ultimate protection against fugitive emissions.

To further enhance the accuracy of the system, Bremerton also specified a corrosion-resistant backpressure/relief valve from Plast-O-Matic. Known as the Series RVDT, these valves provide a constant backpressure on the discharge of the caustic soda metering pumps. This allows for a repeatable, constant fluid discharge per stroke, and enhances the system accuracy. The RVDT further acts as an anti-siphon device, preventing runaway flow of caustic in the event of a malfunction.

Source: Plast-O-Matic Valves, Inc.