New safe, reliable, cost-effective SPX Flow Pumps for transfer of hot oil and hot water

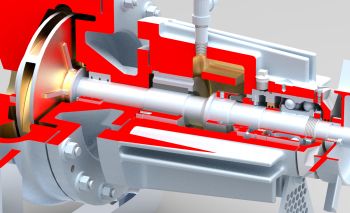

The new CombiTherm Plus pump provides safe and reliable transfer of hot fluids without the need for additional, external cooling systems. The pump is available in two configurations suitable for the pumping of hot oil or hot water and provides an efficient and cost-effective pumping solution.

SPX Flow

The air-cooled CombiTherm Plus pump 4provides safe, efficient transfer of hot oil or hot water in a wide range of applications including injection molding, chemical processing, asphalt / bitumen and tar processing, deep frying systems, steam generators, fuel heaters and heat recovery systems. The pump keeps fluid temperatures uniform to ensure processes are efficient and predictable while its design protects seal faces and bearings from the heat of the fluid; ensuring durable, low maintenance, long life operation.

The design of the CombiTherm Plus pump provides enhanced cooling using optimized cooling fans and large fins to keep the temperature around the shaft sealing below 220 °F even at high process temperatures up to 660°F. The heavy duty centrifugal pump is centerline mounted which allows thermal expansion without affecting shaft alignment. The combination of low temperature and perfect alignment protects seals and bearings meaning that the unit provides long life while minimizing maintenance overheads. The pumps are designed to handle high pressure throughout their flow range with hot oil pumps operating up to 360 psi and hot water pumps up to 450 psi.

Both SPX Flow CombiTherm Plus hot oil and hot water pumps use a balanced single mechanical seal that is easy to position and assemble for straight forward maintenance. To prevent the grease from being washed out of the ball bearings, in case of a mechanical seal failure, the bearings are protected with two separate seals and an open drain. To prevent wear on the shaft, the out-board seal of the quench chamber is running on a hardened shaft sleeve and the ball bearing area is sealed using contact-less seals. The use of a journal bearing cartridge makes maintenance and replacement exceptionally easy. The CombiTherm Plus hot oil pump has an open quench system with visual level indication and optional remote leakage detection. The hot water model comes with a steam eliminator on the seal chamber.

Overall, the CombiTherm Plus range is designed for safety, efficiency and high availability. Their robust design makes them ideal for tough applications such as tar and asphalt and, without the need for additional, expensive cooling systems, they offer a very attractive solution. Available for flows up to 1330 GPM, the modular CombiTherm Plus range comprises nine sizes in both hot water and hot oil model configurations to match many different application needs. Units are sized so that they can be easily interchanged with other high-end pump versions so operators can easily upgrade and benefit from the extended life, reliability, reduced maintenance and excellent cost/performance ratio the CombiTherm Plus offers.

Source: SPX Corporation