New K+S Salt Extraction Plant Is Brought Online with Engineering Support from Celeros

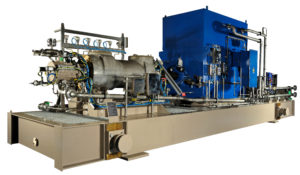

Overview of the two new CUP water injection pumps for single and parallel operation, following installation and commissioning at the Frisia Zout BV site. (Image source: Celeros Flow Technology)

Frisia Zout BV, part of K+S Minerals and Agriculture GmbH, was able to overcome the time and technical challenges of accelerating the project by working in partnership with Celeros Flow Technology (Celeros FT). Celeros FT provided high specification pumps and specialist engineering expertise throughout the installation and commissioning phase. They will continue to ensure the pumps operate satisfactorily throughout the plant’s 15-year lifespan.

Production challenges

Frisia Zout BV produces around 1.2 million tonnes of high quality salt each year for use in industrial processing, food production and water purification. This involves the extraction and processing of approximately 10,000m3 of brine per day.

The salt is extracted under licence from the Dutch Government. Due to regulatory changes, a new licence would only permit extraction from subsea sources off the coast, rather than on land. Consequently, a new borehole and associated plant was required at their Frisia Zout BV site.

K+S began planning for a new pump building in 2017, and construction began in April 2020. However, unforeseen difficulties with the existing onshore well meant that it became imperative to bring the new offshore well onstream as soon as possible.

Time pressures were not the only challenges the company faced. The new plant is fed by one of the deepest wells in the world and has 5km of pipework beyond the water injection pumps. As a result, the process water has to be pumped in at high pressure (250 barg) and at a high flow rate (450 m3/h) to extract the amount of salt required – making the choice of pumps critical to success.

Total solution

Celeros FT assessed the flow requirements for the water injection process at the new plant and verified that CUP-BB3 pumps could be made to meet requirements. The pumps were specified with Duplex stainless steel casings because they would be operating in a salt-laden environment. ClydeUnion Pumps manufactured and supplied the pump packages, as well as installing and commissioning them. In addition, they supported Frisia Zout BV in bringing an older pump back into service as a spare: assessing it and upgrading the casing to ensure it met the new duty requirements.

The company’s ability to meet the accelerated project deadline is particularly impressive when you consider that the COVID-19 pandemic was already affecting supplies of materials and components. The Celeros FT team worked hard to ensure that this did not have any impact on their customer.

Jouk Riemer, project manager for Frisia Zout BV, says: “The combination of high quality OEM equipment and practical engineering skills offered by Celeros Flow Technology was instrumental in delivering this project ahead of time. I’m convinced it would have taken a lot longer to get what we required from another pump manufacturer. The company’s responsiveness was crucial in meeting our revised deadline, reducing costs and keeping extraction at this site viable.”

Future assured

The new salt extraction plant came online in December 2020. Its CUP-BB3 pumps meet the high pressure and flow rates required for the application and can run in parallel, which has improved productivity. The availability of a spare pump gives extra confidence that production downtime will be minimal.

The new well has an operational life of 15 years, though the pump building may be required to serve more than one well in future as demand for K+S high purity salt continues to grow. Easy replacement of wear parts and ongoing service support from Celeros FT will ensure that the BB3 pumps continue to meet operational parameters throughout the extraction plant’s lifetime.

Source: Celeros Flow Technology