New Inpro/Seal Smart CDR Brings Intelligence to Shaft Grounding

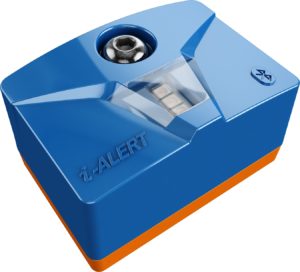

Inpro/Seal announces the introduction of the Smart CDR. The Smart CDR is an innovative condition monitoring system that provides users with instant feedback on the performance of their CDR (Current Diverter Ring) in diverting shaft currents away from bearings to ground.

Variable Frequency Drives (VFDs) are becoming the system of choice across a variety of industries due to their ability to reduce energy consumption and generate significant cost savings. However, these systems induce high-frequency voltages on the shaft that seek a path to ground, discharging through the motor’s bearings or through the bearings of coupled equipment. This discharge, called electrical discharge machining (EDM), causes fluting on the bearings and is a leading cause of premature bearing failure in VFD-driven motors. The CDR uses proven technology to divert these harmful shaft currents to ground.

Now, the Smart CDR provides a simple interface to alert users in real time if there is not optimal contact between grounding brushes and the shaft – preventing bearing failure. If contact has been interrupted, routine maintenance can be performed to return shaft grounding to peak performance.

Source: Waukesha Bearings Corporation