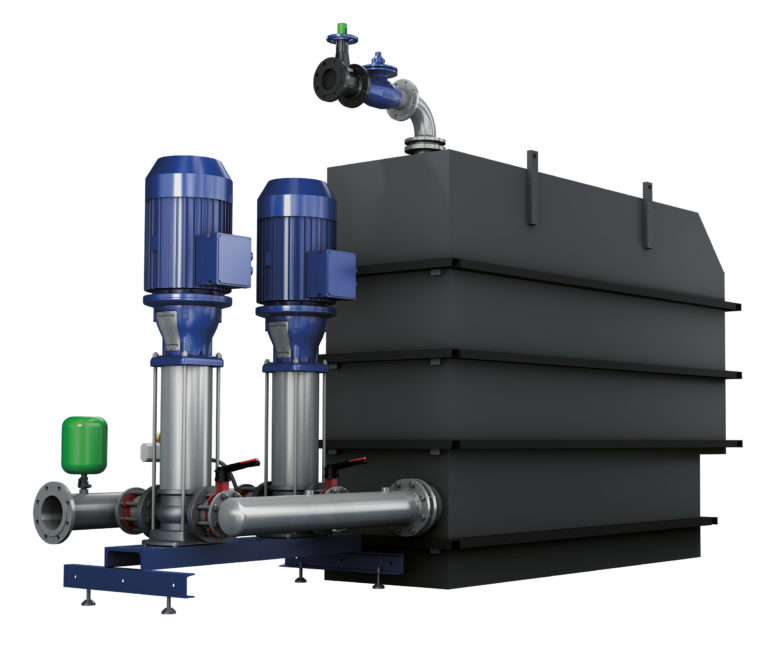

New, Fully Automatic Break Tank Package Booster Set for Fire Fighting

In the event of a fire, the new, fully automatic break tank package booster sets for fire fighting of the type Hya-Duo D FL-R can pump 192 cubic metres of fire-fighting water per hour. (Image source: KSB)

The fully automatic break tank package booster set for fire fighting is fitted with two fully redundant pumps, each of which has got their own power and control circuit. Their redundant control systems continuously monitor pressure switches and limit switches for broken wires and short circuits. Motor protection and dry running protection are disabled in the event of fire, making sure the pumps do not stop before fire fighting has ended.

The master switch and valves are secured against unauthorised operation. If one of the pumps fails, the redundant control system takes over and starts up the second pump. This provides a high level of safety for the operator, the buildings to be protected and the infrastructure.

The break tank ensures that drinking water and fire-fighting water are hygienically separated to EN 1717 type AB. The net tank volume meets the 3 percent rule stipulated in the standard. The modular design makes the system easy and fast to instal and connect to the water supply, saving both time and money. Emergency drainage of the break tank is not carried out by the fire-fighting pumps but by a separate solution matched to on-site conditions.

Mains water supply is effected via a DVGW-approved inlet valve at inlet pressures between 1.5 and 5 bar. Drinking water and fire-fighting water are hygienically separated from each other in compliance with the DIN EN 1717 and DIN EN 13077 (type AB) standards. In combination with regular flushing of the valve microbial contamination of drinking water is ruled out.

An automated daily functional check run increases the operating reliability and ensures that the operator is always informed about the operational status of the system. If space is at a premium, the required tanks with type AB overflow for the hygienic separation of drinking water and fire-fighting water can be welded together on site. The system is exclusively manufactured in Germany.

Source: KSB SE & Co. KGaA