New Electrical Isolation Pads Make SX Plants Safer

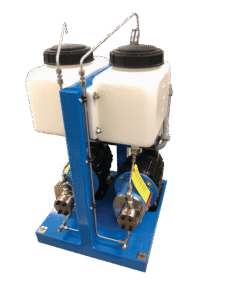

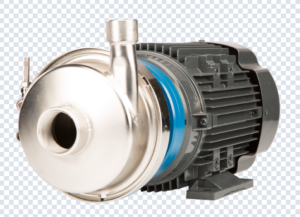

The polymer, Vesconite, has been installed by SAM Engineering on base plates upon which its centrifugal pumps are mounted. (Image source: Vesconite Bearings)

The motors are flame proof; they are ATEX certified, a European safety standard for electrical equipment in hazardous environments.

Vesconite is thus not required to isolate against stray current coming from the motor as all motors are fitted with earth studs.

"Instead, the Vesconite pads isolate the pumps against stray current that travels in the copper solution or other equipment in SX plants,” says Rowen Govender of SAM Engineering’s Technical Sales Department.

Like many polymers, Vesconite is a good insulator. What makes it different to other polymers is that it is dimensionally stable and does not absorb water. Importantly, it handles high static load without deformation, and this is critical for SX pumps, which are heavy.

Govender informs that "the 400 kW motor coupled to the SAM pump supplied to SX plants typically weighs 3,500 kg, and pumps 2,000 - 2,500 m3/hour to a head of 40 - 45 m."

Each pump is mounted on to three Vesconite isolation pads that are located, in turn, on a stainless-steel base.

SX plants are the heart of the copper processing operation. Fire protection is important to prevent loss of life, and to reduce the likelihood of plant fire, which could result in significant equipment replacement costs and considerable costs if the plant is not operational for lengthy periods.

SAM Engineering has had considerable success in harsh mining and processing environments. It prides itself in custom pumps made for operation-critical applications.

Source: Vesconite Bearings