New Becker O5 Rotary Vane Vacuum Pumps for Food Packaging

Gebr. Becker is expanding its range of rotary vane vacuum pumps in the O5 series by the sizes O5.10, O5.16 and O5.21. These pumps have been specially developed for applications in the food packaging industry. The pumps have a maximum flow rate of 10 to 23.5 m3/h.

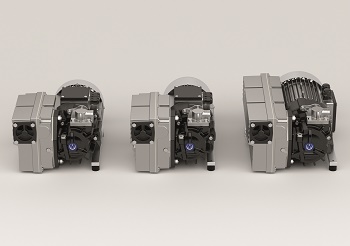

The compact dimensions of the three new rotary vane vacuum pumps in the O5 series allow optional integration in the same machine. (Image: Gebr. Becker GmbH)

The extremely compact design of the new vacuum pumps is one of their design features: All three pumps have a construction height of only

160 mm. This opens up the possibility for manufacturers, especially of

tabletop packaging machines, to build machines with smaller dimensions and to achieve better ergonomics. The almost identical dimensions also allow a modular machine setup: All three pumps can be optionally integrated in the same machine. This gives the machine builder flexibility and also gives the user additional options when selecting the machine.

The pump design is also based on modularity: All three models can be optionally equipped with a small or large oil tank and motors with a different power output. From the perspective of the machine manufacturer, this makes it possible, for example, to offer the option of a premium version with a bigger oil tank and a correspondingly larger air deoiling element, in addition to a compact basic version with a smaller oil tank, which enables not only longer maintenance intervals but also increased water vapour

tolerance. The oil tanks can be split for easy, residue-free cleaning of the tanks.

Thanks to the modular design, Becker can also offer the user of the new vacuum pumps various options for the position of the oil filler opening, oil drain and oil sight glass. This simplifies both the service process and the 1 to 1 substitution of the O5 series in existing machine designs. The innovative and patented twistlock on the air deoiling element ensures quick replacement and maximum serviceability.

Regardless of the size and equipment chosen, the pumps in the O5 series stand out with their robust design and highly reliability. Neither low ambient temperatures or contaminants in the oil or frequent start-stop cycles without a long lead time affect their service life. Another feature is the quiet operation, which is achieved by the special geometry of the discharge valve.

With these features, the new Becker rotary vane vacuum pumps in the O5 series, first introduced at the IFFA 2019, are ideally suited for the vacuum packaging of fresh or perishable products (meat, fish, sausage and cheese) as well as for other applications in which reliable and efficient vacuum generation is required.

One of the pilot users of the O5 series is VAMA Maschinenbau in Wilpoldsried, a leading supplier of vacuum chamber machines for the food industry and other user industries. VAMA considers the requirements that the company places on vacuum pumps to be implemented very well in the O5 series: Managing director Kurt Hörburger: “We need pumps that are characterized by compact dimensions, running smoothness, quiet operation and high reliability. The rotary vane pumps from Becker have this broad property profile.” That s why VAMA already uses the new pumps: Gebr. Becker s IFFA booth exhibited a compact VAMA tabletop vacuum chamber machine, which generates the vacuum with an O5.16 type pump.

Source: Gebr. Becker GmbH