iTOK – New TOK for Industrial Applications

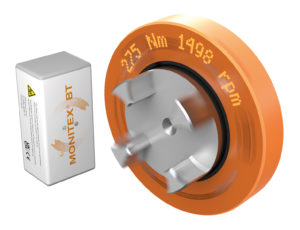

iTOK – new TOK for industrial applications. (Image source: REICH – Dipl.- Ing. Herwarth Reich GmbH)

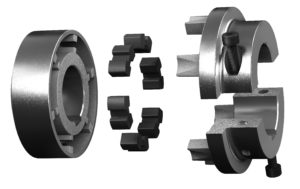

The highly flexible iTOK coupling has been specially designed for applications requiring extremely low torsional rigidity. As the direct connection between the engine and the driven machine, it can compensate particularly well for axial, radial and angular misalignments on resiliently mounted drives. This allows torsional vibrations and load shocks to be optimally absorbed while ensuring smooth running of the drive.

“We have drawn on our exceptional experience with torsion-optimised couplings from numerous test bench applications for the industrial sector to specifically focus on the development of TOK. The iTOK allows us to offer our industrial customers the ultimate combination of torque transmission and torsional flexibility,” emphasises Christian Reich, Managing Director of Dipl.-Ing. Herwarth Reich GmbH.

Torque transmission capacity meets displacement capability

The iTOK combines high torque transmission capacity with high displacement capability making it suitable for high speeds. The iTOK coupling design incorporates coupling sizes for a torque range of 600 Nm to 60,000 Nm as standard – and customised REICH couplings even up to 140,000 Nm. The rigidity of the coupling can be adapted to requirements by selecting different elastomers. All iTOK couplings are maintenance-free and comply with ATEX explosion protection.

REICH-Kupplungen has a variety of iTOK versions in its range: this provides the duplex variant of iTOK with double the torque, while the R version (in series) enables the iTOK’s rigidity to be halved. The modular design allows for a wide variety of configurations with minimal assembly effort. This makes the iTOK a compelling, custom-fit and cost-effective solution for industrial customers who aim to achieve a high level of operational stability for their system.