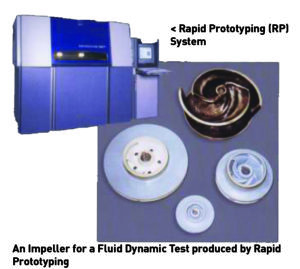

Herborner Pumpentechnik Introduces New Maintenance Sled for Sewage Pumps

Herborner presented the new maintenance sled for sewage pumps for the first time.

The Universe-P process pump as an example for using the new maintenance sled: The maintenance sled greatly simplifies maintenance tasks on sewage pumps (Image: Herborner Pumpentechnik)

Despite the use of special sewage impellers designed to handle large amounts of solid material, sewage pumps can get clogged up at the impeller – especially when a lot of non-woven tissues are used. This typically requires disassembly of the pump.

In most cases, disassembling a sewage pump is a two-person job. Lifting equipment has to be installed to remove the heavy and bulky parts of the pumps. In many cases, the entire pump has to be removed from its pipe before the clogging can be removed. Herborner Pumpentechnik is now introducing a quick solution to these problems: the maintenance sled for the Univers series.

The maintenance sled will be available for the Univers-A and UNnivers-P series, and will considerably simplify maintenance and service of these pumps. In order to access the replacement unit, only the screws between the back panel and the pump housing have to be removed. Then, the rear part of the pump can be removed from the pump housing without a lot of force or the use of lifting equipment. This creates a large enough opening to remove any remaining clogging from the pump impeller and replace any damaged parts. Once all maintenance tasks on the pump have been completed, the sled can be pushed back onto the pump housing before fastening the back panel to the pump housing.

Special features of the maintenance sled from Herborn

The maintenance sled is equipped with heavy duty casters that are sized to handle the weight of the relevant components. The casters can be used in almost any environment and work reliably even after longer periods of use.

The integrated, pre-fitted track system ensures a repeatable and precise mounting of the replacement unit and prevents lateral shifting on the basic frame of the pump. In addition, an adjustable bearing plate serves to compensate for radial and slight axial misalignments in order to position the replacement unit to match the precise orientation of the pump housing.

Using a clamping mechanism on the mounting plate, the pump can be secured in its maintenance position to prevent unintentional movement along the track system. This mechanism fastens the mounting plate with the base frame, and can be easily released to let the sled move freely again once maintenance is complete. The sled can also be bolted to the base frame in the fully assembled state in order to reduce vibrations.

The Univers series maintenance sled will be available for all Univers-A and Univers-P pumps for the nominal diameters DN80–DN200. Previously installed pumps cannot be replaced 1:1.

To further simplify removing the replacement unit from the pump housing, the optional puller assembly is recommended. It can be mounted to the maintenance sled and removed while out of use in just a few steps. This especially reduces the difficulty of maintenance tasks on larger pumps, drastically cutting down pump service time.

All in all, the Herborner maintenance sled can simplify work and increase efficiency in the area of rough operation of sewage pumps, once again proving how innovative the engineers at Herborner Pumpentechnik are.