Greene Tweed Highlights WR600 Thermoplastic Composite

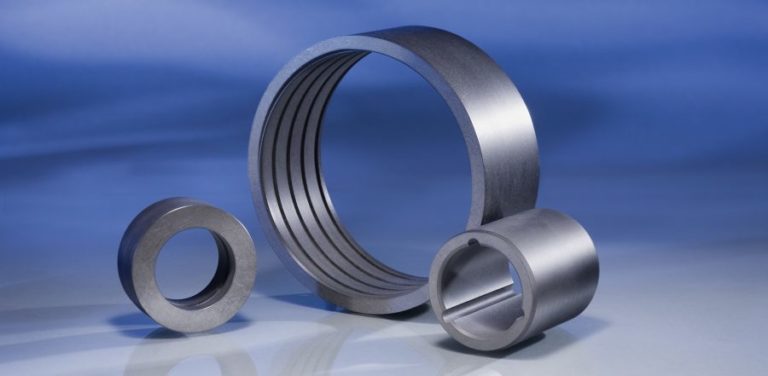

WR600 Thermoplastic Composite offers nearly universal chemical compatibility and corrosion resistance. (Image source: Greede Tweed)

The WR600 thermoplastic composite can withstand continuous service temperatures up to 500°F (260°C) and is ideal for stationary wear rings for static applications; pump applications in refineries, chemical plants, power plants, and water treatment plants; as well as all types of centrifugal pumps.

WR 600 withstands the strongest acids, bases, halogens, and solvents. Its non-galling properties facilitate extended periods of dry running during upset conditions. Featuring excellent impact and thermal shock resistance, WR 600 tolerates rapid startup or shutdown without the risk of fracture or pump failure. Components made of WR600 run tighter clearances than traditional metallic materials, reducing recirculation and improving efficiency. This results in substantial energy savings, extended service life, and improved mean time between repairs.

Components made of WR 600 will have improved dry run properties, compared to standard materials, that will extend pump reliability and lifetime. Quick and easy machining to exact finish dimensions reduces pump repair turnaround time and increases equipment availability. In addition, WR 600 improves vibration damping for increased pump life.

With comprehensive in-house machining centers, Greene Tweed offers finished WR® 600 parts, along with stock shapes in many sizes. Greene Tweed’s engineers provide expert assistance in determining the best material and design for each application.

Source: Greene, Tweed & Co. – Corporate