New Labyrinth Seals Avoid Galling and Failures

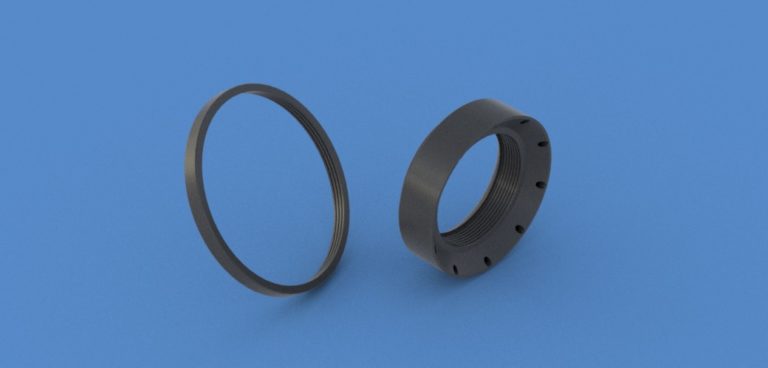

Some of the labyrinth seals that Vesconite Bearings produces. (Image source: Vesconite Bearings)

Labyrinth seals are mechanical seals that provide a long path for water to flow through to prevent leakage. As the name suggests, these seals may be composed of a large number of grooves acting as labyrinth chambers. The labyrinths help reduce the leakage flow through the seals.

Vesconite bearing materials have proved valuable in these seals as they are self lubricating. As a result, during shaft rotation, when parts of the seal come in contact with the shaft, high temperatures and even galling are avoided. This is unlike traditional stainless steel and bronze labyrinth seals, where contact leads to high frictional forces, rapid increases in contact temperatures, galling and even catastrophic pump failures.

Vesconite labyrinth seals can also be designed to optimise their performance. Since there is no threat of galling, close clearances can be applied. This is important since the smaller the clearance, the lower the flow of water past the seal and the higher the efficiency of the pump.

Vesconite bearing materials offer the advantage of being more economical than their stainless steel counterparts, and much quicker to machine. Vesconite can be machined easily to produce complicated grooves for water limiting flow and for securing the seal, and have completely replaced stainless steel parts in many pump applications.

Source: Vesconite Bearings