EagleBurgmann´s Dry-Running Agitator Seal

When EagleBurgmann launched SeccoMix1 on the market, it introduced a shaft seal for agitators that can be used in mixers, agitators, dryers and filter strainers. The dry running single seal in semi-cartridge construction consists of a sprung unit and a stationary seat unit which is very easy to assemble.

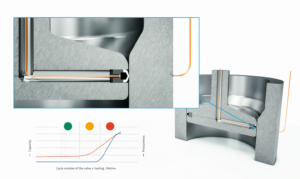

EagleBurgmann SeccoMix1 – stationary seat with patented circulation holes (Image: EagleBurgmann)

The construction and operating conditions of dry-running seals caused considerable noise emissions due to the lack of lubricating medium. In addition, these seals generally gave off a great deal of heat during operation. These disadvantages have been eliminated with the SeccoMix1. Constructive measures ensure the seal operates quietly, and the patented air cooling system for the seal face has significantly reduced the rise in temperature. As a result, the SeccoMix1 can also be used in explosive areas (ATEX), making it unnecessary to monitor the temperature for category 1 (zone 0).

Since dry-running SeccoMix seals do not require supply systems, they have an advantage over liquid- or gas-lubricated seals. The investment costs for a dry-running single seal are only approx. 30% of a correspondingly liquid-lubricated seal due to the costs saved on procurement and operation of a seal supply system.

Standard SeccoMix1 single seals are used for top driven machines and for non-hazardous process media. Available for side entries – as often found in dryers – is the SeccoMixR variant with rotating counter ring. The abrasion is so low that the SeccoMix1 can easily be used in the food and pharmaceutical sector.

Advantages at a glance

- Compact, easy to assemble unit (semi-cartridge)

- Torque transmission without damage to shaft

- No noise development, no squeaking

- Heat dissipation via circulation holes

- High operational safety and long service life

- No temperature monitoring required for ATEX category 1 (zone 0)

- Improved planning of seal maintenance through wear marking

- FDA-compliant materials

Operating range

Shaft diameter: d1 = 25 …160 mm (0.98" … 6.30")

Greater diameter upon request.

Pressure: p1 = vacuum … 6 bar (87 PSI)

Temperature: t1 = -20°C …+150 (+250*)°C

(-4°F … +302°F (+482°F*))

*with cooling flange

Sliding velocity: vg = 2 m/s (7 ft/s)