Drying Gas Under Water: Safe Glycol Injection for Natural Gas Production

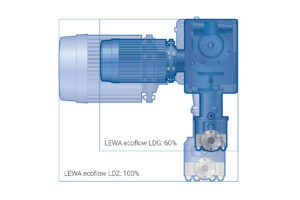

IA total of three pumps will be installed per production branch, with one pump being kept available as a stand-by unit. This results in an output of about 36 m³/h MEG. (Image source: LEWA GmbH)

This can be impaired by underground salt domes in caverns, which can cause the extracted gas to have an increased degree of humidity, in turn hindering later compression. The moisture must be removed by injecting glycol and thus drying the gas. This is necessary in a French mineral oil group's current project. After acquiring production rights off the north coast of Mozambique, the group has begun preparations for extensive LNG production. Since the offshore units through which the natural gas is produced are not located on a platform but underwater, the glycol is pumped from the coast via pipelines directly to the production sites. LEWA Nikkiso America Inc. was commissioned to provide the pumps required for this purpose. It is a subsidiary of LEWA GmbH, which is known for its expertise and has been active in this field for over 60 years. For the time being, two of a total of seven planned production branches were to be equipped with process diaphragm pumps.

"The biggest challenge in this project is certainly the combination of high back pressure from the production site and the large amount of monoethylene glycol required, which has to be conveyed to the well around the clock. The MEG must be injected continuously despite this pressure," said Holger Henze, Regional Sales Manager at LEWA GmbH, which is responsible for manufacturing the pumps at the company's headquarters in Leonberg. "At the same time, we have to ensure that the pumps are 100% reliable so that even maintenance does not lead to an interruption in the gas drying process and thus to a costly delay of the entire pumping process. Last but not least, the aggregates should function as economically as possible."

Flow rate of 18 m³/h per pump at 517 barg back pressure

To counter these problems, the responsible persons at LEWA decided to use the proven triplex pump with pump heads specially designed for this application. "The G3U variant in combination with the M800 pump head enables a flow rate of 18 m³/h per pump, despite the high back pressure of 517 barg," explained Henze. A total of three pumps will be installed per production branch, with one pump being kept available as a stand-by unit. On the one hand, this results in a flow rate of about 36 m³/h MEG and on the other hand, the reserve pump can step in if maintenance work has to be carried out on one of the other pumps. Reliable, constant injection is thus ensured and interruption of natural gas production is largely excluded.

"The pump heads are special models that can also work with a PTFE sandwich diaphragm, thanks to a diaphragm clamping system designed for high pressures," said Henze. "Comparable pumps must otherwise be equipped with a metal diaphragm to withstand the high pressure. However for design reasons, such diaphragms are hardly feasible in the size for the drive unit used in this power class." At the same time, the pump head takes up less space and is more compact than models with the stiffer metal diaphragm, which would require a much larger diaphragm diameter for the same degree of displacement. This would automatically lead to a larger pump head diameter. In order to reduce pulsations and avoid vibration-induced damage, resonators are also used to ensure that the medium flows evenly. Like the base plates, they are manufactured at the LEWA Nikkiso Middle East plant in Sharjah (United Arab Emirates). The final assembly, including the piping, will take place in Leonberg.

"The first three pumps have already been successfully accepted by the customer and the operator after a final acceptance test (FAT), so we plan to deliver them in mid-October," reported Henze. "The remaining pumps will also be thoroughly tested at our Leonberg plant before being shipped to Mozambique. This is to ensure that there are no surprises on site. We are also confident that the other production branches can also be equipped with pumps from LEWA."

Source: LEWA GmbH