Amarinth Provides Pumps With Acoustic Anclosures to Meet Offshore Platform Regulations

Amarinth has designed and supplied an innovative compact acoustic enclosure for its API 610 OH2 produced water treatment pumps to meet strict health and safety regulations on an offshore platform in Qatar.

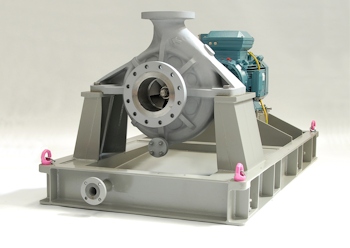

Amarinth API 610 pump with the acoustic enclosure removed (Image: Amarinth)

When Maersk issued the design standard for a new produced water treatment plant for one its offshore production platforms in Qatar, in order to meet Health and Safety regulations Maersk stipulated a maximum noise level for the pumps of 80db(A). Although Health and Safety regulations differ slightly around the world, a broadly accepted maximum level for continuous exposure to noise over an eight hour working day is 85db(A).

The contract for the produced water treatment plant was placed with Alderley who in turn turned to Amarinth, with whom it has a long established relationship for oil and gas projects, to supply the necessary API 610 OH2 pumps with Plan 53B seal support systems. This placed the responsibility on Amarinth to meet the 80db(A) noise levels for the pumps, and furthermore supply the pumps on a tight 28 week delivery.

Historically, noise levels for produced water treatment plants on offshore platforms have varied depending on where they are sited and who is working near them. Amarinth determined that for the pumps to meet the design standard their noise would have to be reduced. On measuring the noise levels for the motor and wetted-end separately however, Amarinth found that the motor noise was less than 80db(A) but the wetted-end was higher, which took the overall noise levels above the 80db(A) design standard.

The solution from Amarinth was therefore to design a bespoke baseplate placing the pump and motor on the left and the seal support system with its air cooled piping on the right. This enabled Amarinth to design a compact and cost-effective acoustic enclosure for just the wetted end of the pump which would fit within the space constraints of the rig, allow for regular maintenance and reduce the overall noise to the required level.

For ease of maintenance and full 360° access to the pump and motor, the acoustic enclosure was quickly removable without the need to disrupt any pipework. However, it also had to remain in-situ near the pumps when removed as there was nowhere else to move it to on the rig. This required modelling the human elements during the design stage to determine how people could work around the enclosure effectively. A maintenance hatch was also provided in the enclosure for regular access to the oiler.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “For good reasons Health and Safety regulations are becoming ever tighter and reducing noise levels for continuously operating equipment on offshore rigs helps protects workers from exposure to long-term damaging noise levels. All parties are delighted with our acoustic enclosure that both reduces noise to the required level and ensures that regular maintenance can be carried out without any disruption to schedules or additional downtime. I am sure we will see more requirements for innovative designs like this in order to meet tighter regulations in the future and we look forward to working with the oil and gas industry to deliver against these.”

Source: Amarinth Ltd.