ELLIOTT Releases the Model 140TCH Pipeline Compressor

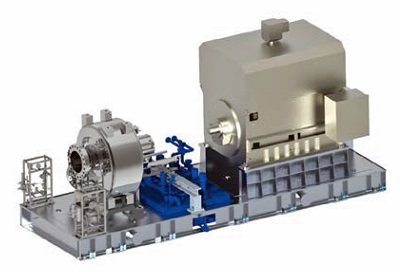

ELLIOTT releases the Model 140TCH Pipeline Compressor. (Image source: Elliot Group)

The Model 140TCH pipeline compressor is available as an electrically driven solution for new and replacement pipeline stations with stringent NOx and CO2 emission requirements. The advanced design of the 140TCH represents Elliott's commitment to sustainability in response to evolving environmental concerns and increasingly complex restrictive emissions regulations. The compressor package includes a 140TCH centrifugal compressor with a direct-coupled, high-speed induction motor driven by a variable frequency drive (VFD) connected through a standard flexible coupling. A standard gearbox solution is also available.

The Model 140TCH Inline Compressor

- Direct connection, variable speed drive (VFD) motor and standard footprint.

- Custom aerodynamics for optimum efficiency

- Extended uptime between scheduled overhauls

- The gearless configuration of this compressor package offers a number of advantages: smaller footprint, lower lubricating oil requirements and higher efficiency.

- The single-stroke pipeline compressor's plug-and-play design includes ancillary equipment (lube oil, buffer gas panel, and integrated custom controls), and piping and wiring are included on the skid for quick and easy installation with less field labor.

- Seamlessly available for applications from 10 to 35 MW.

- Easy access to the compressor's internal parts contributes to lower maintenance costs.

"In the United States, the natural gas situation has changed with the development of local shale gas production and the subsequent focus on reducing emissions. For these projects, the electric-powered engine solution is optimal. In Europe, the increasing need for natural gas imports to change the gas transmission and transportation and distribution network, and electrically driven compressors are accepted as a low-emission alternative to gas turbines," says Product Introduction Manager Todd Omatick.

Compressors play an essential role in maintaining pressure and flow as natural gas moves through pipelines from extraction, processing and storage to the end user. In its E-Vision 2030, EBARA Group has set a goal of achieving net zero carbon emissions by 2050 and contributing to the creation of a sustainable society.

Source: EBARA CORPORATION