Hamworthy Pumps makes strong re-entry to tanker market

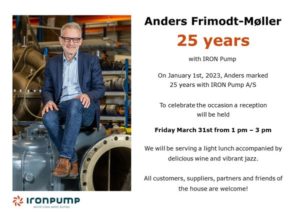

Shuttle tanker "Tove Knutsen" (H3114) which was delivered to Knutsen from HHI. Hamworthy Pumps has delivered pump room systems for both the H3114 and the sister ship H3115, which will be delivered in a few weeks. (Image source: Hamworthy Pumps)

In Singapore, Hamworthy Pumps is back on its feet as an independent brand following a change of ownership. As part of an ambitious growth plan, the company has embarked on a comeback within pump room systems for tankers, where it was one of the leading suppliers to this market for decades.

Resently the new strategy has resulted in orders for pump room systems for three large tankers, with an option for a fourth. Two of the ships – both Aframax-size crude oil tankers – are being built by Hyundai Heavy Industries for the Finnish oil refiner Neste. The third – a 152,000 DWT DP2 shuttle tanker – is being built at COSCO Zhoushan Shipyard for Knutsen NYK Offshore Tankers of Norway.

“We have a strong ambition to gain market share in pump room systems. Neste and Knutsen are crucial references for us in that context. We continuously develop our solutions in close co-operation with end-users, ship designers and strategically selected vendors. With these orders, we send the message that we have the expertise and the setup to deliver the customized pumping solutions that the market demands”, says Terje Bjornemo, Director, Pump Room Systems at Hamworthy Pumps.

Expanded facilities and water cooled motors

The orders for pump room systems for the three shuttle tankers have all been won in a new powerful alliance with Hoyer Motors as the subcontractor for electrical drive systems. The Danish electric motor specialist has many years of experience from the marine industry and will be a strategically important partner for Hamworthy Pumps’ re-entry to the tanker market.

“In recent years, we have strengthened our capability to serve the marine industry including expanded facilities in China and a new range of ATEX and IECEx certified, explosion proof marine motors. For these specific tankers we developed special water cooled motors to meet the PRS requirements and will continue to invest in R&D as we strongly believe in the tanker market potential,” says Henrik Sørensen, CEO, Hoyer Group.

The collaboration between Hamworthy Pumps and Hoyer Motors is further strengthened by the fact that both companies are in the process of significantly upgrading on service and aftersales. Last year, Hamworthy Pumps opened a large service centre in Singapore together with its sister company Svanehøj, and it is currently rolling out a new global service provider concept. Hoyer Motors has taken active steps into the aftermarket and is represented via selected partners in Houston, Rotterdam, Singapore and Shanghai, among others.

FACTS: The scope of supply for the Knutsen / COSCO Zhoushan Shipyard contract (N786)

The pump room system consists of:

- 3 X Cargo Pumps of capacity 4000m3/h @ 135 mlc, Casing and Impeller in superior Ni-Al-Bronze material.

- 3 X Gas Tight Power Transmissions.

- 3 X 2-Speed Electric Motors – 6,6 kV – max power output 1894 kW each motor. Water cooled.

- 1 X Two Spindle Screw Pump for Stripping of Cargo Lines and Air/Gas Separators.

- 1 X Gas Tight Power Transmission.

- 1 X Electric Motor.

- 2 X Ballast Pumps, Casing and Impeller in superior Ni-Al-Bronze material.

- 2 X Gas Tight Power Transmissions.

- 2 X Electric Motors.

- Automatic Stripping- and Capacity Regulating System including 3 X Air / Gas Separators with level monitoring, 3 X Hydraulic Actuated Capacity Regulating Valves after Each Cargo Pump, 3 X Hydraulic Actuated Vacuum Valves between each Air / Gas Separator and Vacuum Pump Units.

- Temperature sensors for all Bearings and Pump Casings, Gas Tight Seal on Power Transmissions.

- Pressure Transmitters for all Pumps - inlet and outlet, Pressure Transmitter on Manifold.

- Vibration Transmitters on each Cargo Pump.

- Level Transmitters on each Air / Gas Separator.

- All overseen by our PLC based Cargo Control System.

FACTS: The scope of supply for the Neste / Hyundai Heavy Industries contract

Each of the two pump room systems consist of:

- 3 X Cargo Pumps of capacity 3000m3/h @ 135 mlc, Casing and Impeller in superior Ni-Al-Bronze material.

- 3 X Gas Tight Power Transmissions.

- 3 X 690 Voltage Electric Motors – max power output 1400 kW each motor. Water cooled.

- 1 X Two Spindle Screw Pump for Stripping of Cargo Lines and Air/Gas Separators.

- 1 X Gas Tight Power Transmission.

- 1 X Electric Motor.

- 2 X Ballast Pumps, Casing and Impeller in superior Ni-Al-Bronze material.

- 2 X Gas Tight Power Transmissions.

- 2 X Electric Motors.

- Automatic Stripping- and Capacity Regulating System including 3 X Air / Gas Separators with level monitoring, 3 X Hydraulic Actuated Capacity Regulating Valves after Each Cargo Pump, 3 X Hydraulic Actuated Vacuum Valves between each Air / Gas Separator and Vacuum Pump Units.

- Temperature sensors for all Bearings and Pump Casings, Gas Tight Seal on Power Transmissions.

- Pressure Transmitters for all Pumps - inlet and outlet, Pressure Transmitter on Manifold.

- Vibration Transmitters on each Cargo Pump.

- Level Transmitters on each Air / Gas Separator.

- All overseen by our PLC based Cargo Control System.

Source: Hamworthy Pumps Pte. Ltd.