Wastewater Treatment Plant Cuts Energy Use With New Biological Treatment System

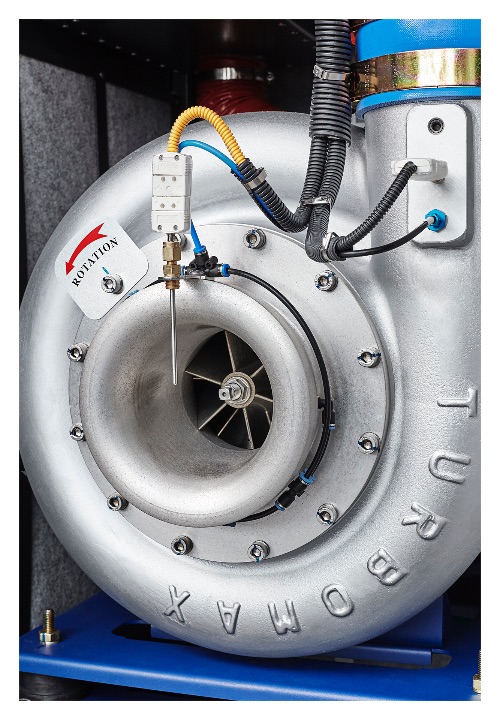

Xylem Turbo blowers. (Image source: Xylem Inc.)

The Alto Seveso plant is located in the municipality of Fino Mornasco, in the heart of Italy’s Como fabric district. Completed in 1978, the plant has expanded and adapted its wastewater treatment line over the years in order to increase efficiency and meet new discharge standards.

Since the plant is only a few kilometers away from the source of the Seveso River, the plant’s discharge can have a significant impact on the quality of the river. In dry weather, 90 percent of the flow of the river is made up of the plant’s discharge. On average, the plant’s discharge rate is 1,000 m3/hour, while the Seveso River has a flow rate of about 100 m3/hour in dry weather.

The owner and operator of the plant, Lariana Depur SpA, needed to reduce the risk of pollutant peaks in its discharge, caused by variations in the input load, while at the same time optimizing resources and energy consumption. A few years ago, Xylem had helped upgrade a racetrack-style tank at the plant, so it called on Xylem to solve this challenge.

Xylem was contracted to revamp the biological treatment process of one train of the treatment plant, a bioreactor where each section can work alternatively as an anoxic or aerobic process, depending on treatment needs. This allows flexibility in reaching the target results depending on variable industrial loads, particularly for nitrogen.

More flexibility and control over treatment processes

Xylem designed the new, industry-leading biological treatment system to enable a huge range of flexibility and control. One way this was achieved was by adding instrumentation and sensors to control six different areas of the bioreactor.

The aeration system was also upgraded and optimized. In a typical wastewater treatment plant, the blowers in an aeration system are the single highest energy consumer. Previously the plant had mechanical surface aerators, which could only operate in on or off mode, so the ability to regulate oxygen was limited. The plant could only turn the aerator off for a few minutes, otherwise settling would occur in the tank. Mechanical aeration is also generally less efficient than fine-bubble aeration.

With the new solution, the plant now has a highly efficient, fine-bubble Sanitaire aeration system, combined with five highly efficient Flygt 4320 adaptive submersible mixers. This solution enables the plant to operate at a reduced airflow for hours or days within sections of the tanks, resulting in significant energy savings.

The Alto Seveso plant now also uses Sanitaire TurboMAX turbo blowers to feed different quantities of air to six Sanitaire fine-bubble systems. Sanitaire turbo blowers are direct-drive, high-speed, turbo blowers using the latest airfoil bearing technology to deliver unmatched results with low energy consumption. They use up to 40 percent less energy than traditional blowers.

The plant’s new PLC-based control system was developed by Lariana Depur with help from Xylem. The system receives process data from Xylem WTW sensors, for dissolved oxygen and nitrogen, and enables the plant to know when to add more air or less air, or no air at all, in which case the adaptive mixers are started to avoid sedimentation in the tank.

Dynamically adjusting operations according to the pollutant load

The upgrades at the plant enabled huge energy savings of 20 percent, or 640,000 kWh a year, compared to the previous system. Much of the energy reduction was achieved by the new ability to dynamically adjust operations according to the pollutant load to be removed. This flexibility is critical since discharge from local textile businesses can lead to highly variable nitrogen peaks loads.

The improvement of the wastewater treatment plant helped Lariana Depur to enhance the water quality of the Seveso River, and consequently, meet the stringent discharge directives regulating the Lake Como area. The upgrade helps the plant to drastically reduce the risk of exceeding the limit of nitrogen concentrations in its discharge (15 mg/l). At the same time, the integrated solution lowers the plant’s energy footprint to make the community more sustainable.

“This upgrade sets a new standard for wastewater treatment in industrial zones, particularly those where there is textile manufacturing,” says Marco Leoncavallo, Customer Excellence Manager, Xylem Water Solutions Italia. “We are proud to partner with Lariana Depur in helping to preserve local water resources.”

Source: Xylem Inc.