Voith Hydro and STRUCINSPECT Advance Monitoring of Hydropower Civil Structures

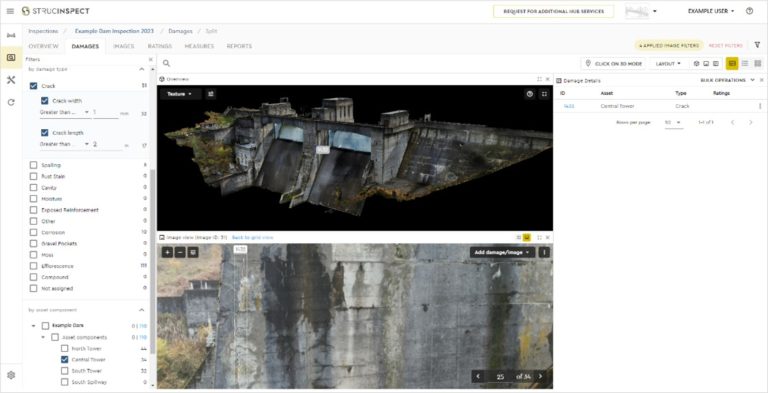

Infrastructure Lifecycle Hub. (Image source: Voith GmbH & Co. KGaA)

To tackle this challenge one of the suppliers of hydroelectric equipment now partnered with the Austrian corporate start-up STRUCINSPECT.

STRUCINSPECT operates the Infrastructure Lifecycle Hub for digital infrastructure inspection and lifecycle management. The web-based collaboration platform is the core of the company’s portfolio and combines technologies and functions to maintain bridges, tunnels, and dams in a safe, sustainable, and resource-saving manner. Based on that STRUCINSPECT supports customers in transforming their existing infrastructure inspection and management into a fully digitalized process. Configurable technology building blocks allow for individual business solutions enabling effective maintenance decisions.

While the solution is already applied in the transportation infrastructure sector the immense potential for (hydropower) dams is now on the rise. Voith Hydro sees great value in the offering for operators worldwide.

“The idea is simple and at the same time ingenious. While it has been very complicated to literally keep an eye on your infrastructure, the digital assessment and tracking of civil conditions is now not only made easier but also safer,” explains Voith Hydro CTO Dr. Norbert Riedel.

Digital inspection in Scotland

A joint pilot project is now performed in Scotland where the inspection of the 72-year-old Clunie station is brought to the next level. Operator SSE Renewables is thereby taking a role when it comes to digital inspection.

“We are excited about the new opportunities this technology brings and happy with the two companies we have on board for its implementation,” says Stephen Crooks, Renewables (Civil) Engineer at SSE. “With this approach, we have all data managed centrally and generate measurable business value out of it.”

“Currently, inspections of the civil infrastructure at Clunie take place physically,“ explains Albrecht Karlusch, Managing Director at STRUCINSPECT. “However, problems might occur in case damages are not spotted during such manual inspections. And this is exactly where the benefits of our digital inspection technology comes into play,” Karlusch continues.

The initial data can for example get collected by drones, underwater devices, or smartphones. This data is transferred to the so-called Infrastructure Lifecycle Hub, where it is getting analyzed by Artificial Intelligence (AI) and a 3D model is being created. Technologies such as Building Information Modeling (BIM) integration or Augmented Reality (AR) can be used as well. In future, digital inspections will be performed in shorter intervals with less manual effort. Even the smallest changes will be identified by the AI-assisted damage detection. This analysis serves as a base for engineers’ maintenance decisions and focuses their precious resources on exactly this core element.

Source: Voith GmbH & Co. KGaA