Unseen but Crucial: The Importance of Monitoring Gas Levels

How to Select the Right Gas Monitoring System for Specific Medical Applications.

While air quality is often ignored in daily life because it is unseen, appropriate air composition is never more important than in the medical environment. Gas monitoring is essential to preserving the safety of patients and the integrity of medical procedures and research. In addition, establishing a regular routine of gas monitoring is crucial to maintaining safe working conditions for medical staff who are continually exposed to specialized, concentrated gases.

Systems for gas monitoring have many uses across medical applications, including health care delivery, in vitro fertilization (IVF) clinics, and medical research, as well as dentistry and veterinarian care. Sound processes for monitoring key gases like carbon dioxide (CO2), carbon monoxide (CO), oxygen (O2) and nitrous oxide (N2O) in these settings require accuracy, speed and efficiency with modern technology that allows for data gathering, reporting and reliable sampling.

Preserving the integrity of research and medical services

Gas monitoring can assist in ensuring safe environments for biological samples, thereby preserving the integrity of lab processes and supporting repeatable, reliable results. Medical research and services that require the use of incubators should rely on regular gas monitoring to ensure the conditions inside the units remain consistent. Incubating cell cultures, bacterial cultures, or embryos such as in IVF clinics require optimal conditions at all times. A regular, built-in process of monitoring CO2 and O2 gas levels is essential for ensuring these appropriate conditions.

Failure to use a sufficiently accurate gas analysis system in the medical setting can be quite serious. In bacteria research, entire culture studies may be lost when carbon dioxide levels become too high or too low. In the IVF process, carbon dioxide and/or oxygen levels need to remain steady, or the specific environment that fragile embryos require for successful fertilization (or even survival) can be compromised.

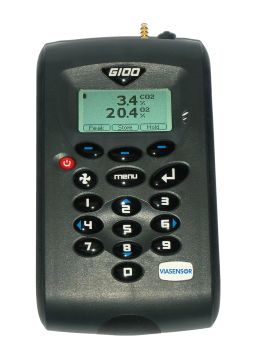

An accurate, easy to manipulate instrument can make all the difference to the success of such a delicate process. Many IVF clinics use the G100 monitoring system by VIASENSOR, which lab personnel appreciate for its convenient size, humidity resistance, accurate carbon dioxide and oxygen readings, and dual-temperature capabilities that allow the user to adjust the environment for greater stability, protecting the cells within the incubator from damage.

Key features of the G100 and G110 include:

- Industry leading accuracy

- Improved stability with in-built moisture removal

- Easy user calibration

- Data storage (1,000 readings) and download

- Larger backlit display

- Longer life battery

- User calibration on analyzer

- Quicker manufacturing and service lead time of 1-2 weeks

- Dual temperature measurements on G100

Gas monitoring for the safety of patients and staff

The use of a reliable gas analyzer is not only essential for preserving biological samples, but also for maintaining a safe environment for patients and staff in the medical setting. For example, nitrous oxide (N2O) was at one time widely used across medical professions to render patients unconscious for treatment. Although no longer the most-used substance for this purpose, it is still used in many other medical applications and research. Since N2O becomes dangerous in large doses, the usage of this gas must be monitored carefully.

According to the Centers for Disease Control (the CDC), waste N2O should not exceed 50 parts per million (50 ppm) during anaesthesia administration. Exposure beyond this level, particularly for health workers exposed repeatedly to N2O, can contribute to an array of adverse health effects including reduced fertility, neurologic issues, and renal and liver disease. To mitigate and prevent these health effects, the CDC recommends regular gas monitoring for airborne concentrations of N2O, implementing appropriate engineering controls and work procedures to reduce exposure, and creating a worker education program that informs employees of both the hazards of N2O exposure as well as the controls, gear and monitoring equipment to prevent or reduce exposure.

The ViaSensor G200 gas monitors are used for monitoring nitrous oxide in a wide variety of medical settings to keep the environment safe for patients and staff alike. The G210 model is relied upon in medical, dental and veterinarian operatories to ensure that the pipes that carry the potentially toxic N20 are free of any leaks. This protects not only the patients but also medical, dental and veterinary staff who could become ill if they are continuously exposed to low levels of a noxious gas like N20.

Key features of the G200 and G210 include:

- Best in industry accuracy

- Improved reliability using CO2 filter

- Lightweight and small size (G210)

- Easy user calibration

- Less frequent return for full calibration

- Download software allows instant results (G200)

- Reduced service costs

- Shorter manufacturing lead time of 2 weeks

- No gas pods (G210)

- Option G210 - O2, CO2, CO

Optimal technology for efficient, quick readings

The technology gas analysis systems employ has evolved considerably in recent years. The advent of digital measurement and infrared technology have created new industry standards that negate the need for the inaccurate, cumbersome technology of the fluid-based measurement systems.

Less advanced gas analyzing instruments use fluids that chemically absorb the gas in question. Using these instruments involves a complicated and time-consuming process of preparation, waiting for the absorbing fluid to settle, pumping in a gas sample, and waiting for the fluid to settle again. At the end of the procedure, the absorbing fluid rises based on the amount of target gas in the sample and the level may be read in a manner similar to a thermometer.

While this fluid-based measurement system is still in use in many medical environments, the technology is outdated and unnecessarily complicated. However, the most important shortcoming of fluid-based gas analyzers is a lack of accuracy. Using fluid absorption to read gas levels relies on many steps that introduce unnecessary human error. The preparation is done by medical employees and the reading relies on the smallest significant digit that can be read with the human eye. The fluid, though it can be replaced once no longer useful, must be tested for viability and when to perform this test depends on human judgment. Many readings could be taken with non-optimal absorption fluid before it is tested and replaced.

Digital technology such as that found in ViaSensor gas monitors ensures a higher accuracy rate than older fluid-based models. Infrared (IR) bench technology for detecting CO2 and electrochemical cells for detecting oxygen make reading a gas sample is as easy pressing a few buttons and attaching the sample tube; the electronic analyzer does the rest. The digital readout is more accurate than measuring a fluid level in a tube by eye, and the readings can be taken quickly with fast verification.

As an example, ViaSensor’s gas analyzers take readings in under one minute; this can make an enormous difference in preserving delicate incubator environments, as discussed in the detailed case study below. The ViaSensor instruments feature built-in moisture removal to reduce error and can measure relative humidity and temperature simultaneously. These gas analyzers can also be set up to take both CO2 and oxygen readings at the same time. This is possible because oxygen is read using an electric chemical cell, which allows CO2 to be read with IR technology in a parallel process.

Look for the ability to track and report gas analysis output

Digital gas analyzers have another advantage over the more manually operated, fluid-based gas monitoring systems. The fact that the fluid-based systems are not electronic means not only that readings need to be done “by eye,” but also that data cannot be easily logged for records or future comparison. Digital gas analyzers like those ViaSensor manufactures have a reading output that is provided clearly on a digital screen for convenient tracking. Those purchasing the ViaSensor G100 series or G200 series are able to download software that creates an interface with the researcher’s computer. There is a further option to add software cables that enable the user to keep the data, reviewing it for analysis and tracking purposes.

Look for convenient calibration

Another often-overlooked feature of a gas analyzer is its need for remote technical assistance with set-up and calibration. Most gas analyzers are manufactured and maintained in Europe (primarily Germany and Switzerland), and need to be shipped back to Europe for calibration. This can create major delays in research as there is the waiting period of shipping the system back and forth overseas. Because ViaSensor is established in the United States, so US-based users of the system will not experience any delays.

Case study: Reproductive Biology Associates (RBA)

In recent years, the Atlanta, US-based Reproductive Biology Associates (RBA) chose ViaSensor’s G100 CO2 analyzers to aid in their IVF procedures. Incubators play a crucial role in IVF and the conditions within the incubators must be optimal at all times. The G100 portable analyzer has improved RBA’s overall success rates for clinical pregnancy and implementation. The digital system offered downloadable software that provided easy comparison studies and data log keeping, to ensure intelligent monitoring and the continued success of the IVF procedures.

Prior to finding the G100 analyzer, the clinic had tried many products but none were suitable. Previous analyzers were usually either too bulky, took too long to register a reading or the measurements varied too much for them to be reliable. There were also risks associated with toxicity and contamination to the incubator environment due to the constant need to open the incubators in order to take a reading. Eventually they came across the new ViaSensor G100 CO2 monitoring analyzer. The clinic decided to start using the G100 in all of its incubators and has been very happy with its performance in boosting overall success rates.

RBA Clinical Embryologist, Thomas Elliott, said: “By moving to the digital portable method with the G100, the clinic has been able to eliminate the risks of toxicity and inaccuracy from its previous CO2 analyzers. Ultimately, we are highly satisfied with the G100 as it portable, is fast and easy to use, and its measurements are reproducible. The G100 can also be used to measure O2 levels, which is an added advantage for us.”

Summary

The best, most up-to-date gas monitoring system is pivotal to sound research, safe patients, and reliable, trackable data. Look for systems with the greatest accuracy, speed and efficiency with modern technology that allows for data gathering, reporting and reliable sampling. Medical researchers and staff will benefit from investing in the most modern gas monitoring technology available to preserve their carefully created work.

Picture: Q.E.D Environmental Systems, Inc.

Source: QED Environmental Systems, Inc.