UK Must Copy Germany If We Want A Circulator Pump Revolution

The UK must follow the German model and offer households an incentive to convert their circulator pumps to new high efficiency models.

ecocirc circulator pump (Image: Xylem Water Solutions UK)

The call for an incentive scheme has been issued by Xylem Water Solutions UK in response to the lack of awareness amongst consumers of the role that circulator pumps can play in reducing household energy consumption and its continuing exclusion from the Government’s Green Deal.

Germany has by far the highest adoption rate amongst European nations for new energy efficiency circulator pumps, in large part due to the existence of a ground-breaking scheme which incentivised consumers to make the switch. The German scheme involved offering homeowners a €100 incentive to upgrade their circulator pumps to more efficient models, which could be reclaimed from their bank in cash once the installation was completed.

Gary Wilde of Xylem Water Solutions UK, one of Europe’s leading manufacturers of circulator pumps, commented: “The circulator pump is a hidden user of energy and consumers will not change unless they are given an incentive. The German model of a €100 cash-back scheme would be an excellent way of highlighting the circulator pump issue amongst consumers and would have a payback period of normally within two to three years.”

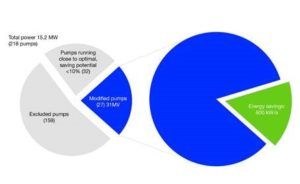

Approximately one million circulator pumps are sold in the UK every year, both stand-alone and those which are integrated within boilers by the OEM sector. It has been calculated that if all standard three speed circulator pumps were converted to variable speed ErP compliant models, the energy savings would be 45 to 65 million Kw’s, with a cost saving over a 12 month period between £63 to £89 million pounds for the end user.

“A traditional fixed 3-speed circulator with an induction motor would require 63W of power,” says Mr Wilde. “However, modern circulator pumps follow the system curve much more efficiently. A new electronic circulator does not put power into the motor to rotate the shaft and can therefore reduce the maximum power to between 6 and 35W.”

He continues: “Modern circulators are also equipped with in-built software which can sense when a thermostatic radiator valve has been closed down and will automatically slow the pump down. In effect, the pump recognises that there is less resistance in the pipework and therefore needs less power which saves energy and money.”

Source: Xylem Inc.