The Pump Systems Assessment Certificate Program

The Hydraulic Institute’s Pump Systems Assessment (PSA) Certificate Program teaches the essential principles and proven processes in managing and conducting pump system assessments.

Participants will learn how to identify high-value pump optimization opportunities and achieve greater energy efficiency and system reliability.

This program covers:

- General concepts of pump system assessment and the importance in industrial and commercial markets

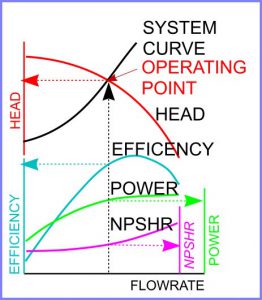

- Hydraulic system behavior and its effect on energy efficiency and reliability

- Pump performance characteristics and the relation to system performance and energy savings

- Identification and quantification of the potential for: energy and cost savings and increased reliability

- Data measurement, collection, and analysis techniques

- Reporting and documentation to build a business case for optimization

- Tools to carry out and manage pump system assessments

Who Should Attend? Pump system owners and operators, energy management professionals, consulting engineers and individuals seeking cost savings and increased system performance.

Format: Divided into eight, approximately hour-long modules (with fully-integrated testing), the on-line course can be taken at its own pace. The PSA Certificate will be delivered upon completion of the exam at the end of the eight modules. Attendees receive 8 professional development hour (PDH) credits upon program completion. Attendees have 60 days to complete this training.

Requirements: Attendees should have basic math skills, knowledge of entry-level hydraulic engineering principles and an understanding of the fundamentals of centrifugal pumps and systems.

Source: Hydraulic Institute Inc.