Sulzer Pumps Presents State-Of-The-Art Technology at Achema 2009

Sulzer Pumps is one of the world s leading pump manufacturers. Sulzer Pumps focus is centrifugal pumps, agitators and mixers for the Oil and Gas, Hydrocarbon Processing, Pulp and Paper, Power Generation, Water and Wastewater and Food, Metals and Fertilizer markets.

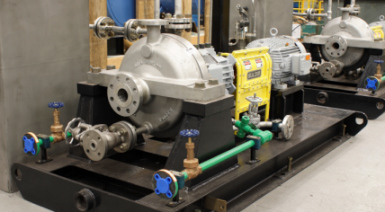

OHHL

The products have an international reputation for technical excellence. Sulzer Pumps operates more than 60 Service Centers worldwide to serve the aftermarket needs of its customers and support the operation of its pumping and other rotating equipment.

Sulzer Pumps promptly addresses its customers needs providing support ranging from the supply of spare parts to full operation contracts supporting equipment throughout its lifecycle.

Featuring at Achema

The OHH horizontal, overhung, centerline mounted, single stage, radially split process pump is designed for use in heavy duty refinery services, petrochemical plants, gas processing and offshore services. The design is according to ISO 13709 (API 610) and ISO 21049 (API 682).

The OHHL is the low flow version of Sulzer s OHH product line. It fills the gap left on the low flow side of conventional process pumps while utilizing the mechanical seals and bearing frame from the OHH. Three casings, three casing covers and two bearing frames are used to achieve 54 OHHL performances. Unlike other low flow pumps, the OHHL utilizes the same standard ISO 21049 (API 682) cartridge type mechanical seals as the OHH.

AHLSTARUP process pumps for pumping of clean, abrasive and erosive liquids and various kinds of stocks. If the liquid pumped contains gas or air, the pump can have with either internal or external gas removal options for stable operation. AHLSTARUP pumps are also suitable for various general applications in the chemical process industries.

MBN multistage ring section pumps are suitable for pumping clean or slightly contaminated liquids, hot or cold, chemically neutral or aggressive liquids in medium or high pressure industrial applications.

With its reliable and innovative design, high efficiency and ease of maintenance the pump is ideal for:

- feed water supply in boiler plants

- condensate supply in power stations and industrial plants

- desalination (Reverse Osmosis)

- shower water in paper mills

- high pressure applications in various industries

Health and Safety at Sulzer Pumps

Sulzer Pumps strives to achieve world class Health and Safety performance. All Sulzer Pumps employees and facilities play an active role in achieving excellence in Health and Safety. As a key component, Sulzer Pumps fosters an attitude of individual and company-wide accountability and responsibility, together with a commitment to continuous improvement.

Quality and Environment at Sulzer Pumps

Sulzer Pumps meets its customers quality and reliability expectations and economically satisfy these expectations by using all its resources in the most efficient way. Sulzer Pumps believes in sustainable development; the goal is to minimize the environmental impact of our operations. By using its products, Sulzer Pumps helps its customers reduce the environmental impact of their businesses. The global quality management system delivers the quality customers expect.

Visit Sulzer Pumps at Achema 2009 in Frankfurt, Hall 8, H5 – J9 and find out why Sulzer Pumps should be at The Heart of Your Process.