Sulzer Launches Ready-fitted Mechanical Seals for Ahlstar A, N and W Range Process Pumps

With the recent acquisition of Tartek Oy, a specialist in development, manufacture, repair and maintenance of high quality mechanical seals, Sulzer has been able to further expand its technology portfolio and now provides in-house designed and manufactured seals for its process pumps.

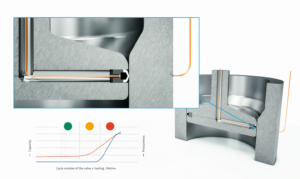

TB2 Ready-fitted Mechanical Seal (Image: Sulzer)

Now Sulzer can provide its first range of new developed TB1, TB1F and TB2 ready-fitted mechanical seals. They are designed mainly to be combined with the Ahlstar A, N and W Range Process Pumps which are part of the Sulzer product portfolio. Those seals fit as well for different process pump types for the seal chamber of the standard gland packing casing cover and for the standard shaft without extra shaft sleeve. The seals have been designed so that any pressure variations or drop-outs of the pumped liquid do not open the seal faces. In order to ensure reliable operation, the ready-fitted seals are constructed as an organic part of certain centrifugal pump types without any extra components. They are mainly designed for industrial applications in the pulp and paper and general industries, but can also be used in the power generation and other markets.

The simple and robust design enables fast and easy installation and maintenance. Therefore, the ready-fitted mechanical seals offers a more economical solution than cartridge mechanical seals.

The new mechanical seals are a result of thorough product development and are tested in real working conditions to ensure reliable solutions. Sulzer’s worldwide sales and service network will introduce the new seals offering globally, both for new business and for the aftermarket.