Statsbygg Selects Framo Pumping Systems for the Norwegian Centre for Ocean Technology

From left to right, Øyvind Hellan, Research Director, SINTEF Ocean, Kjersti Skjelle Paulsen, Project Manager, Statsbygg, Terje Ljones, Sales Manager, Framo Aquaculture. Image source: Framo

The Center will be used by the Norwegian University of Science & Technology (NTNU) and the SINTEF energy research institute to carry out the research, education and innovation that ocean industries require in order to succeed. The goal is to develop and test new technology related to the ocean, increase the safety and efficiency of existing technology, and strengthen Norway's position as a leading ocean technology nation.

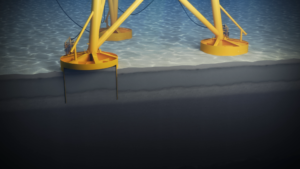

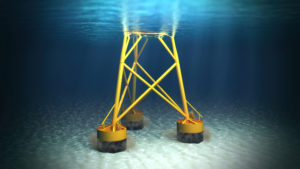

The basin at the research facility is 60 metres long, 50 metres wide, and 12 metres deep, making it possible to test innovations and large, complex structures under realistic conditions. This will allow the development, testing, securing and improving of installations such as offshore structures, ships, fish farms, and ocean wind turbines before they are put into use.

"This is the largest single installation we have ever delivered in terms of pump quantity," said sales manager Terje Ljones of Framo Aquaculture. "Our system will pump enormous amounts of water to simulate ocean currents together with realistic waves. The capacity is 225 cubic metres per second, equivalent to 810,000 cubic metres per hour. That's approximately double the normal flow rate of the Nidelven River in Trondheim. That says something about the capacity.”

Great flexibility

The pump system is designed and developed at Framo's factory on Flatøy island outside Bergen. This is part of a series of pumps with high capacity and low lift heights, which have been initially developed to serve aquaculture facilities. The energy-optimized pumps will be installed in return channels within the pool wall, and will have individual speed control to provide great flexibility in varying the flow rate at different depths. The order also includes water straighteners in front and behind the pump, frequency converters, installation equipment, and a control system that will be integrated together with the plant's main control system.

"This is the first contract for the new pump model SX1000, a permanent magnet motor-driven pump based on the pump systems we have designed and developed since 2018. The pumps have a proprietary motor and propeller blades. The fact that we are now delivering a large series also means that we can invest more in our factories, optimize production, and increase our delivery rate. With this delivery, we can demonstrate that this technology is also well-suited and competitive in other segments besides aquaculture. Statsbygg's choice of Framo is recognition of our capabilities, and an excellent reference for us as a supplier," commented Ljones.

Source: Framo AS